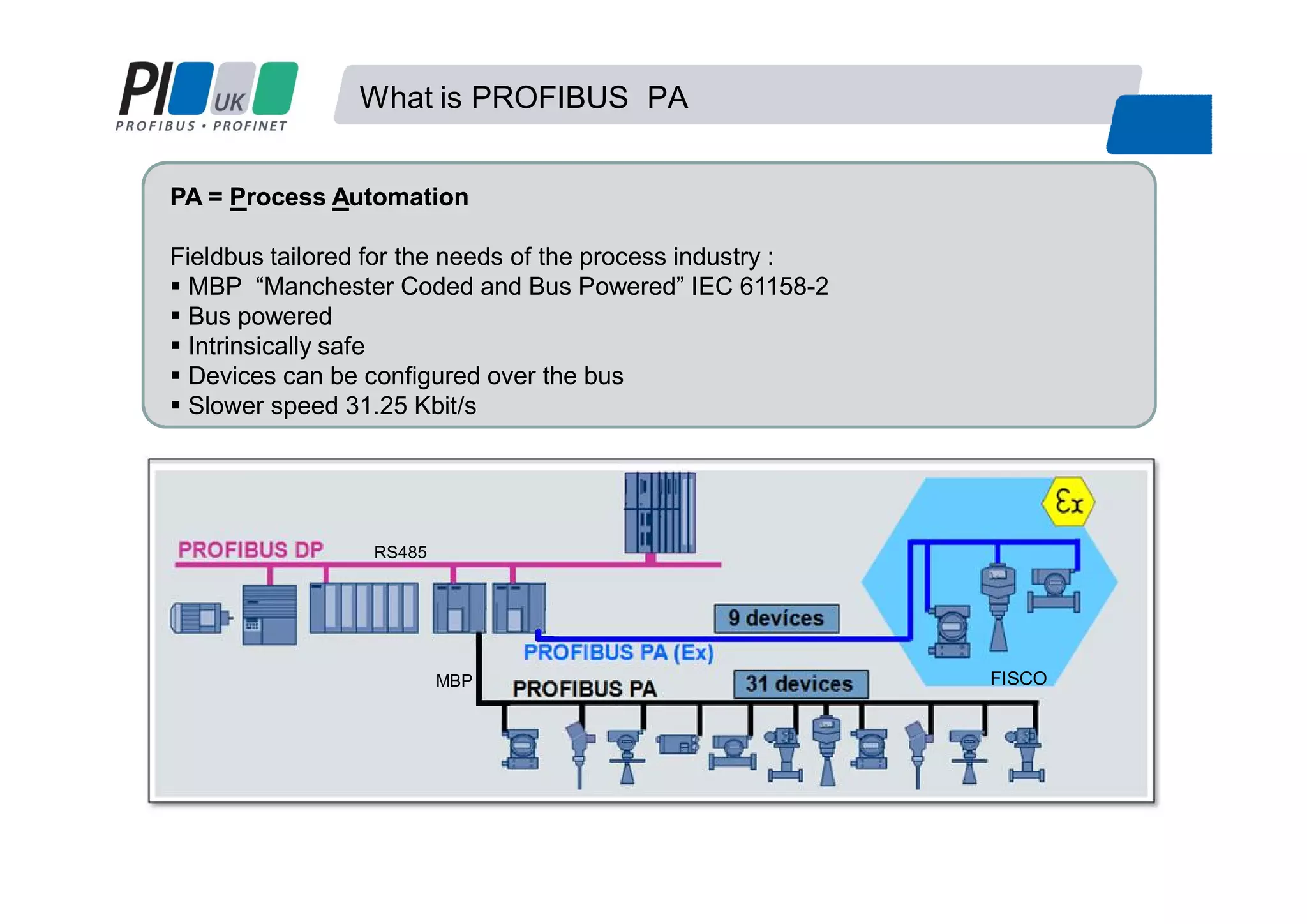

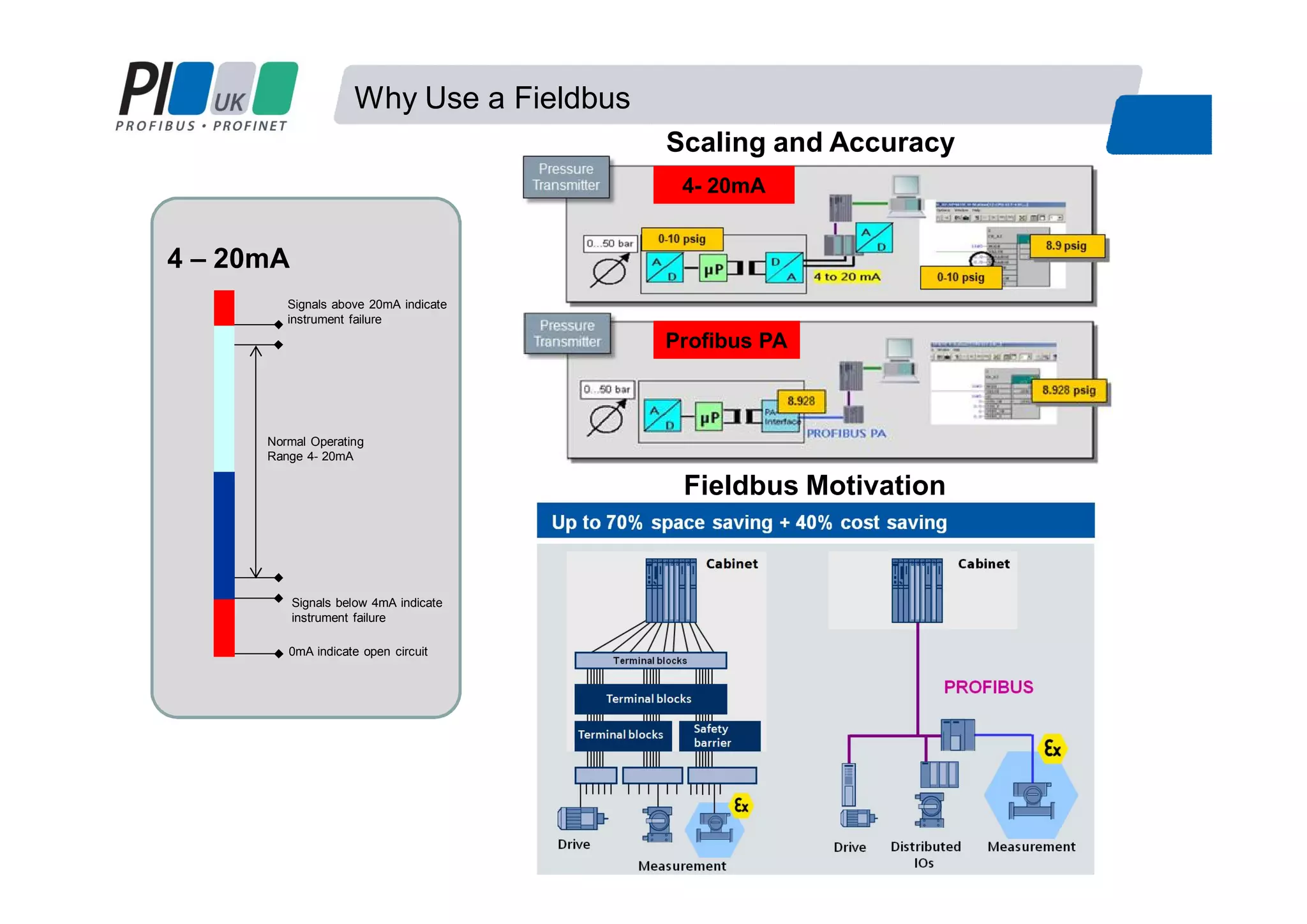

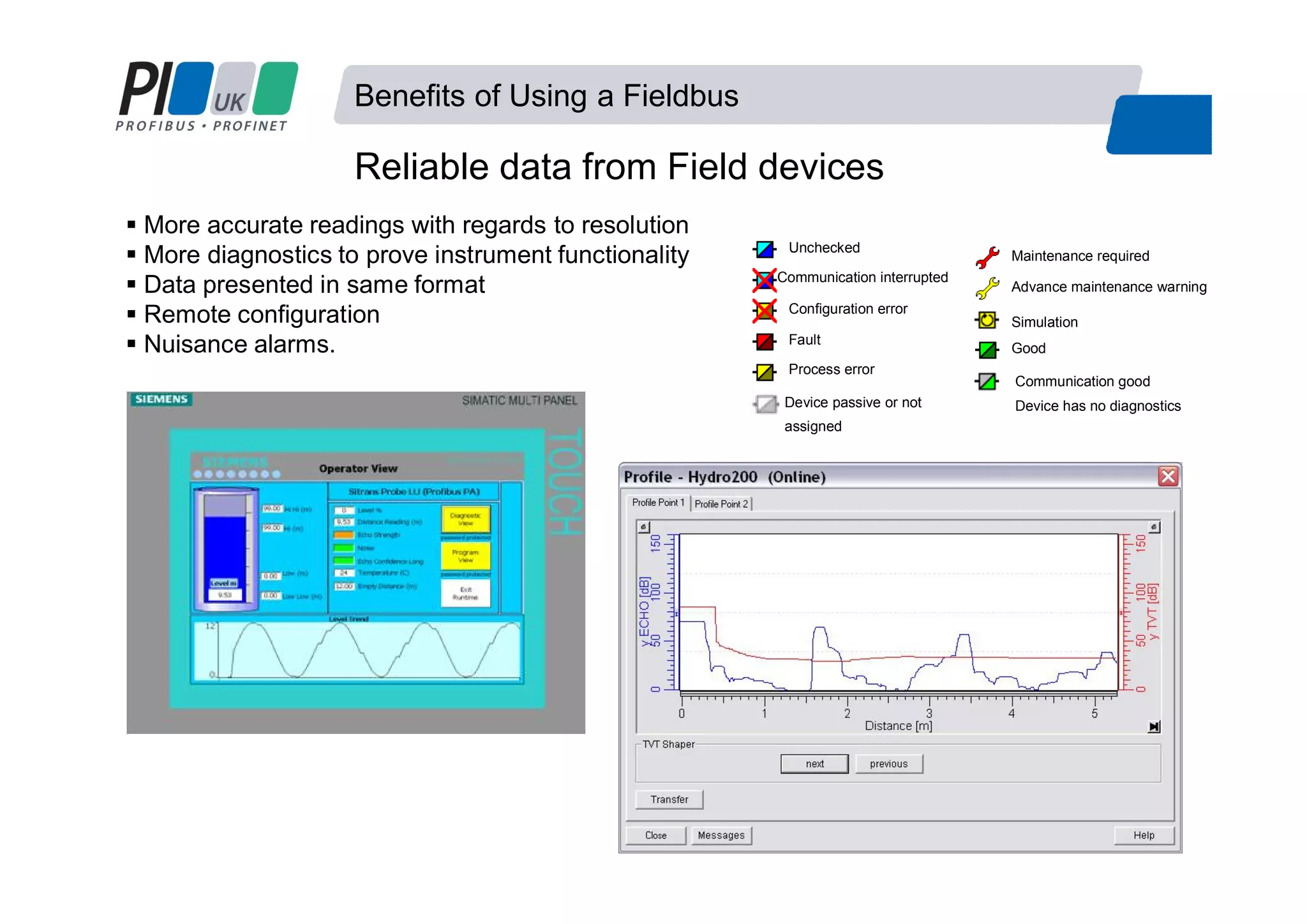

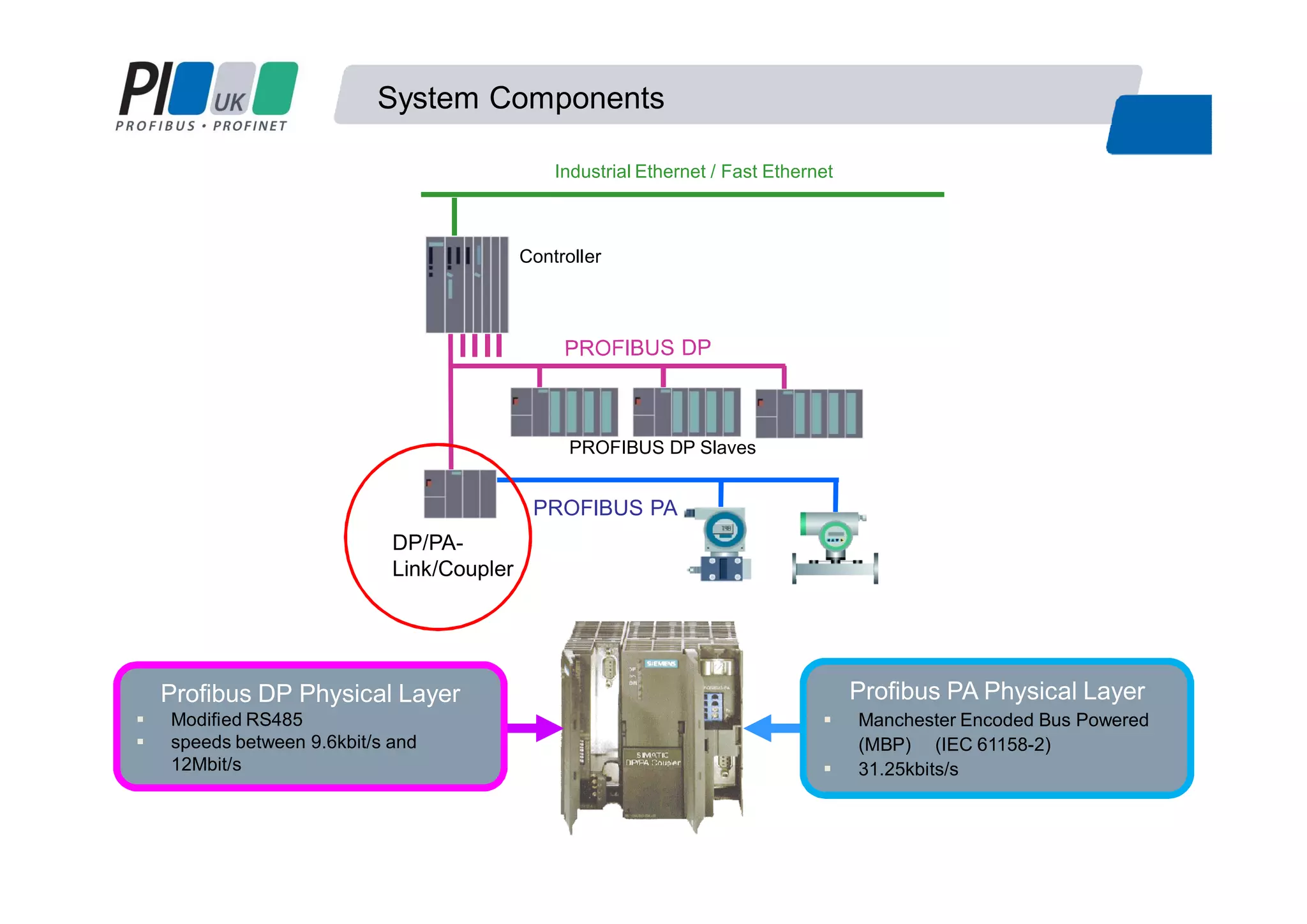

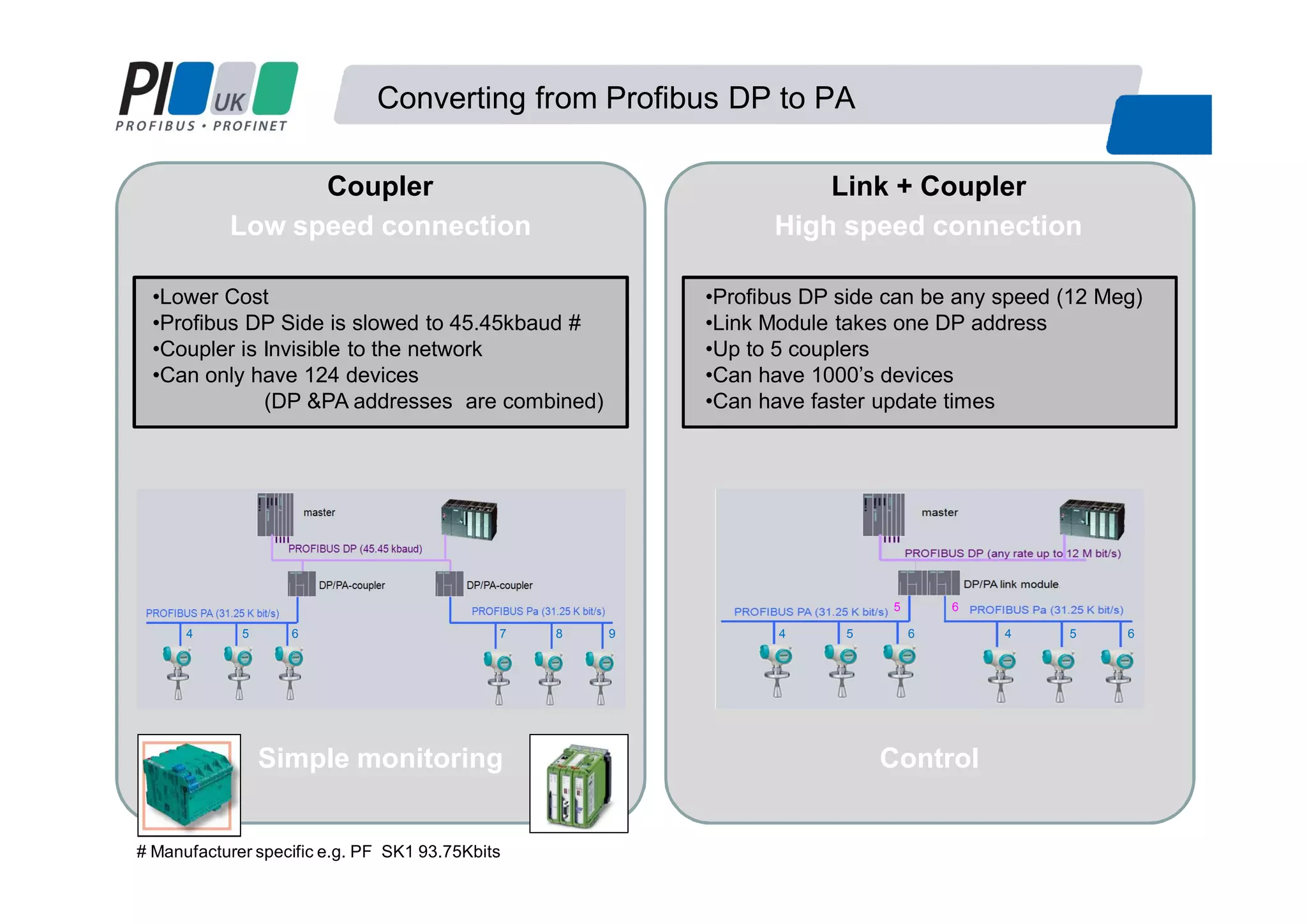

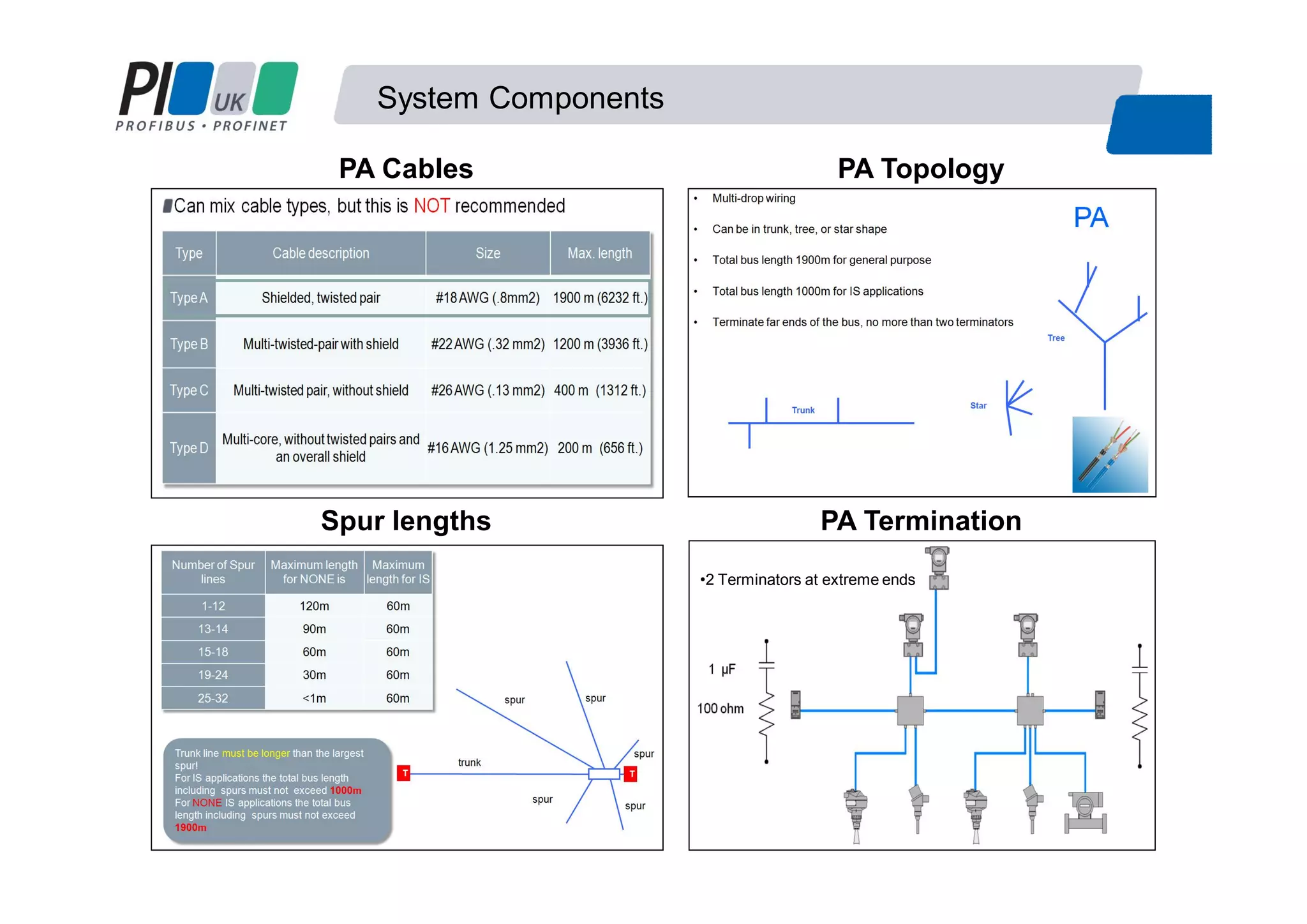

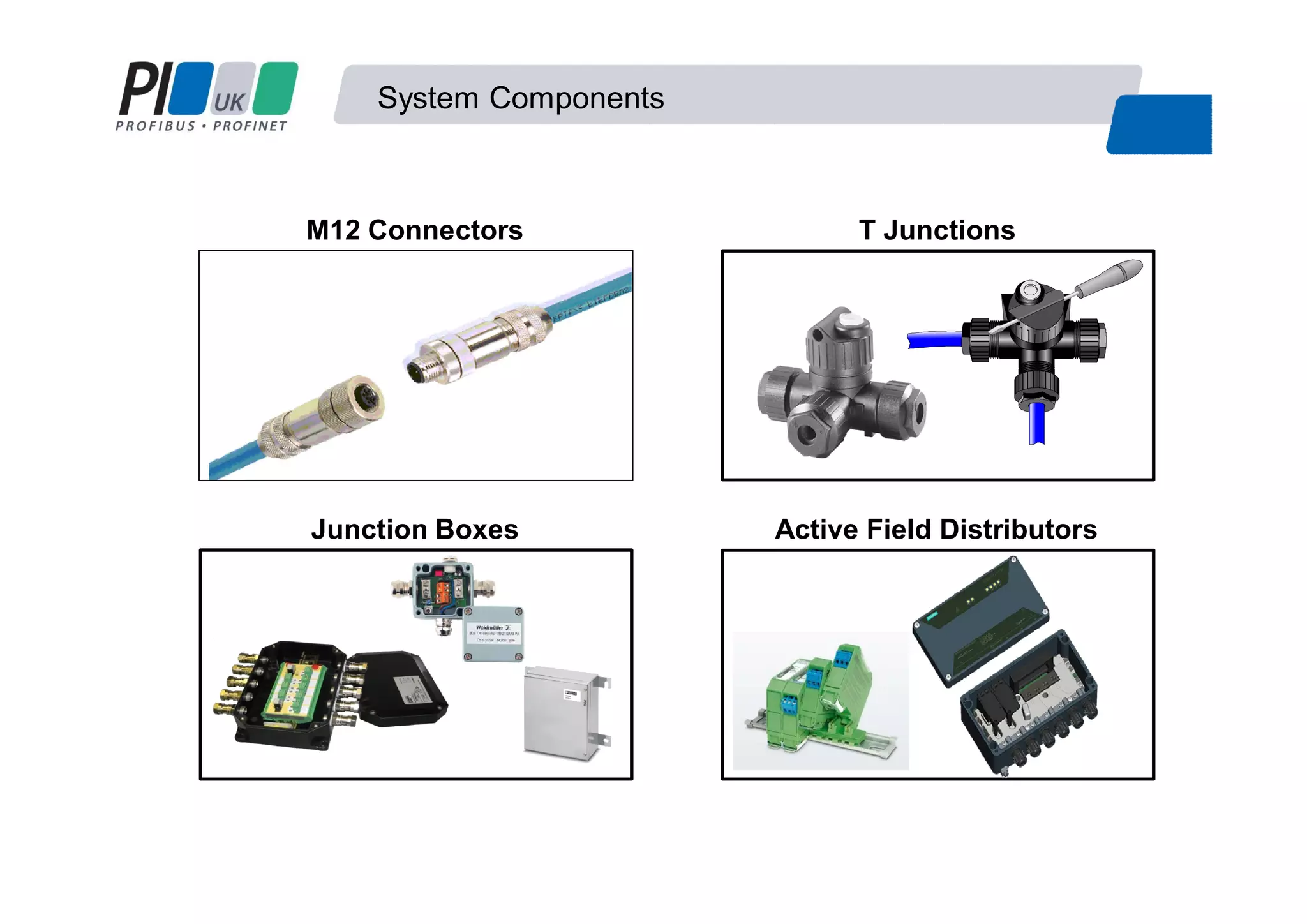

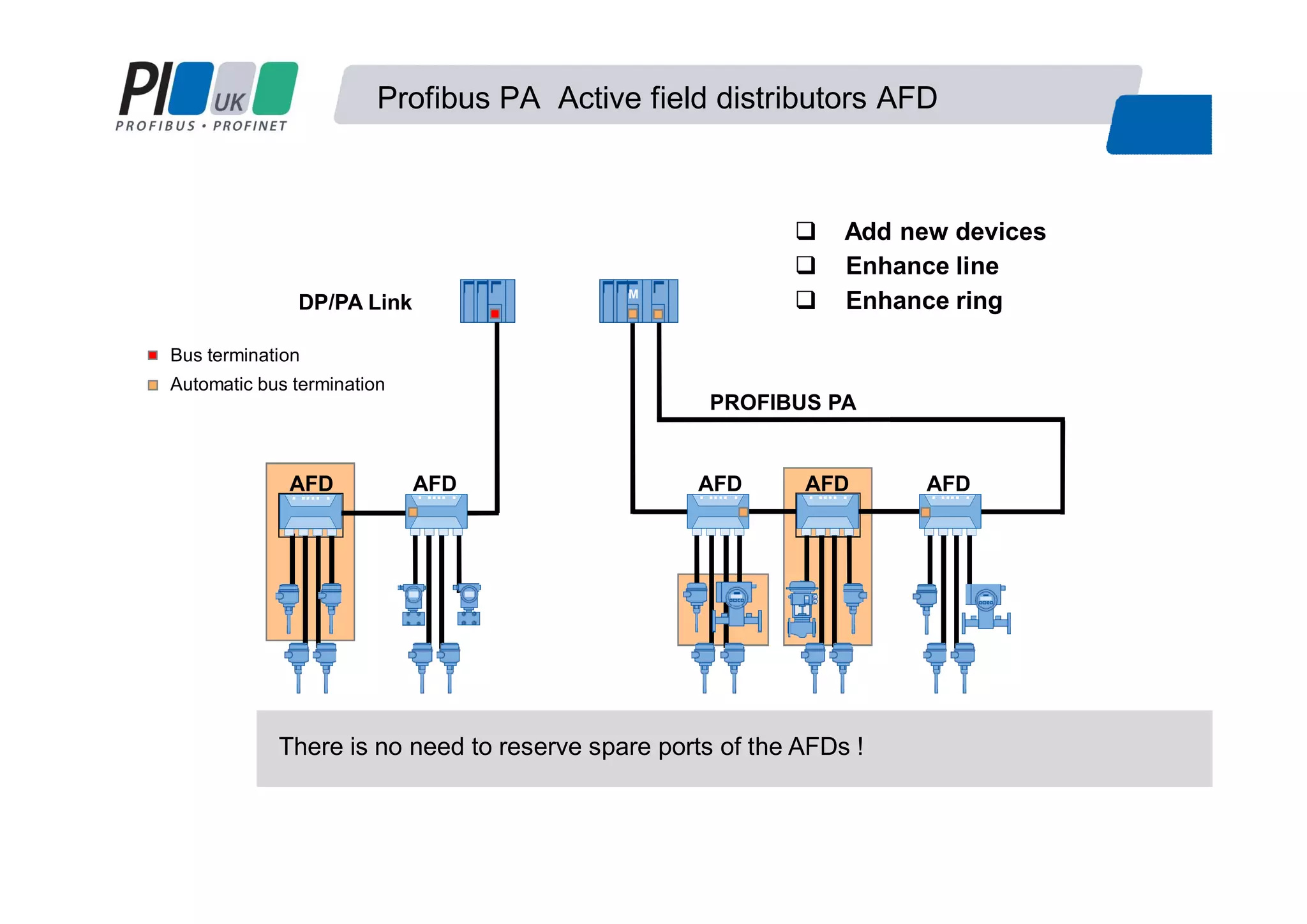

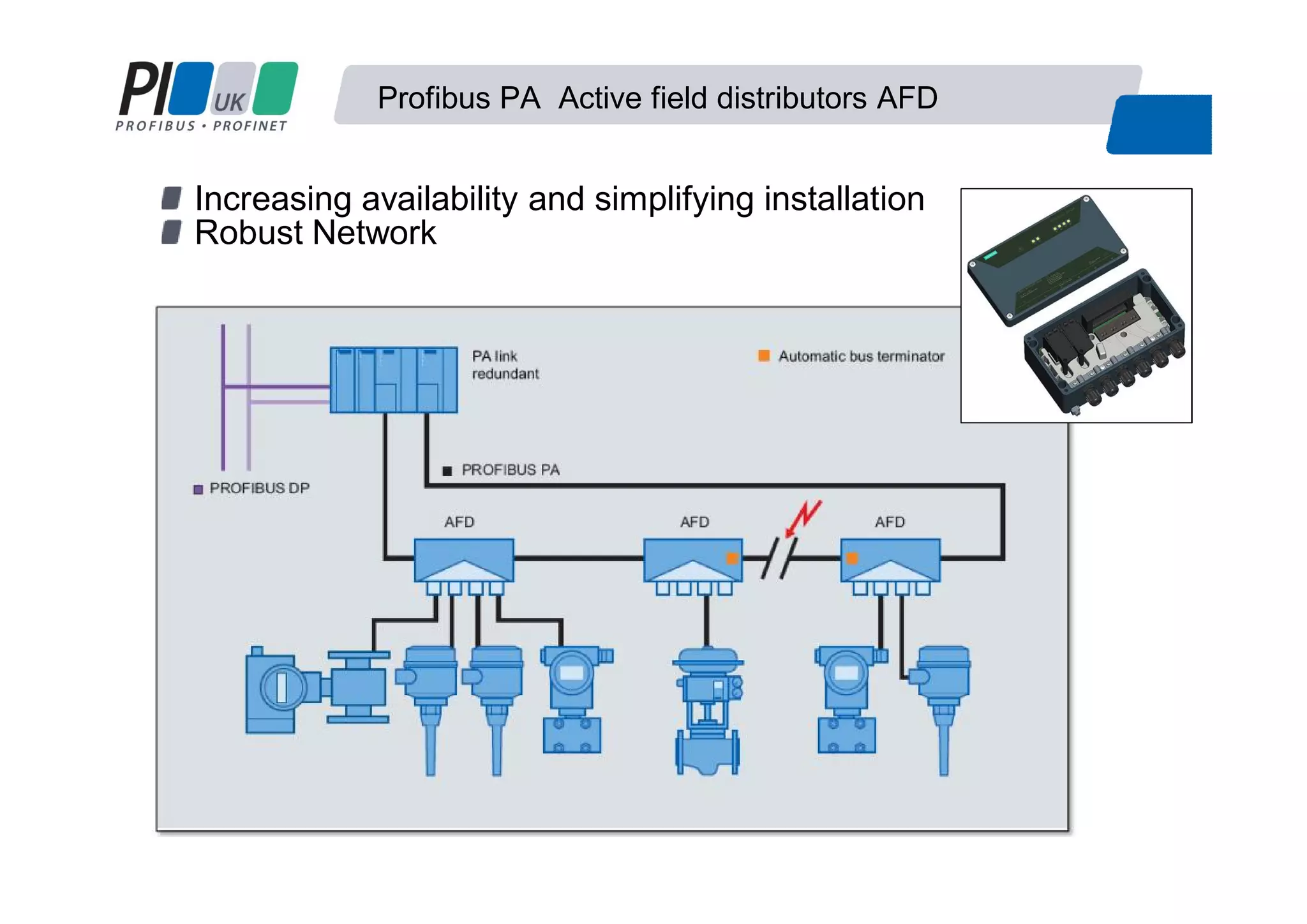

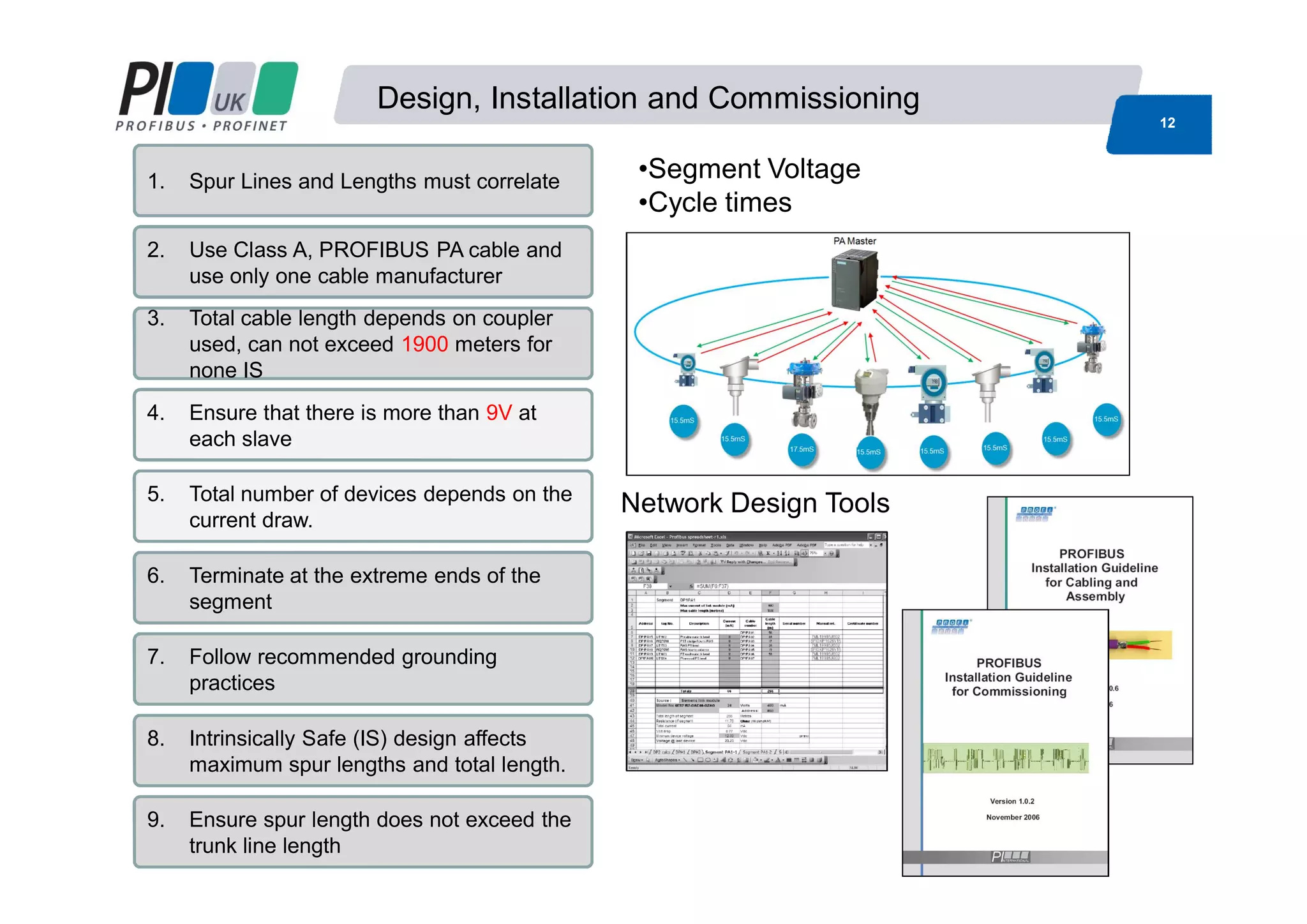

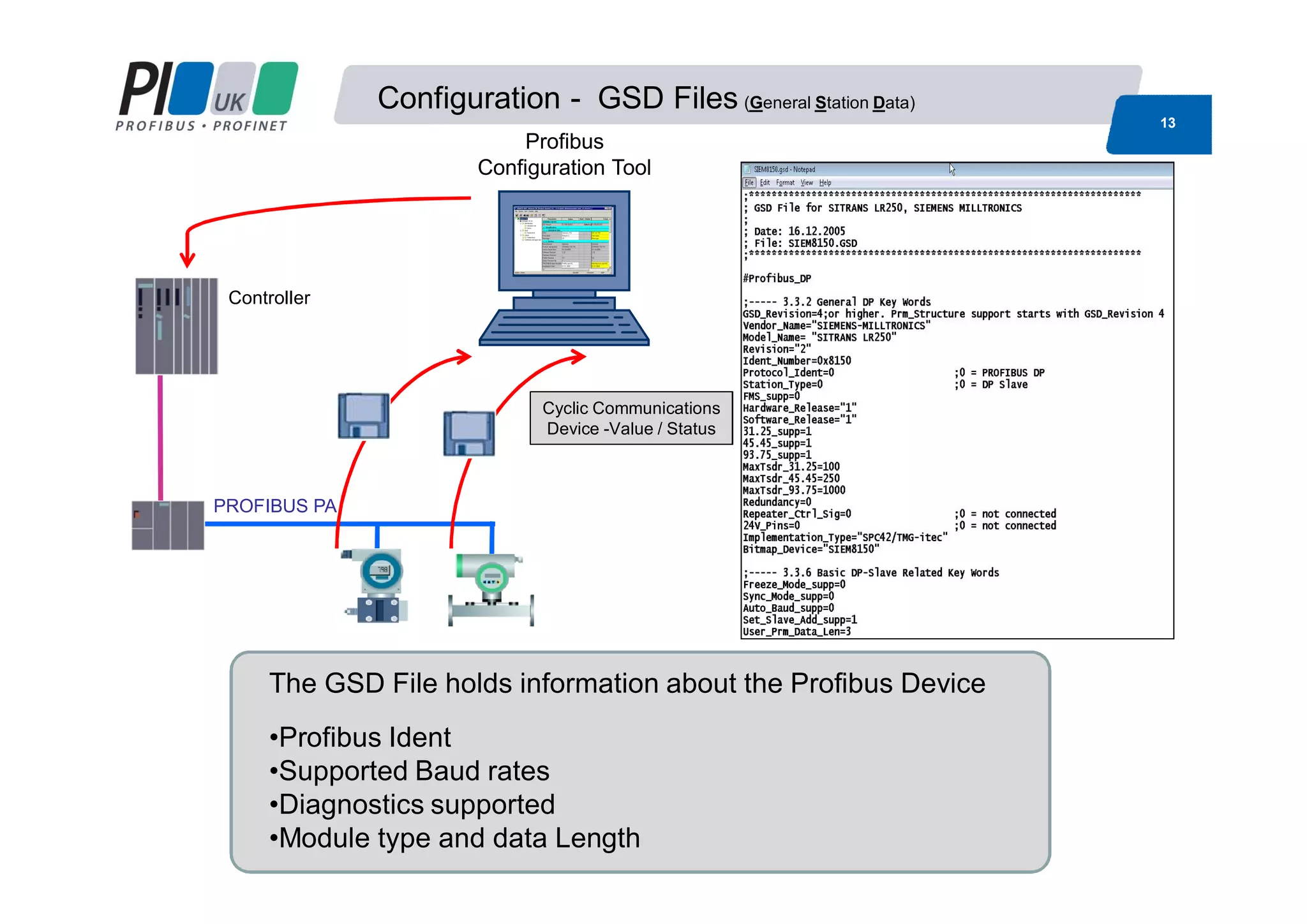

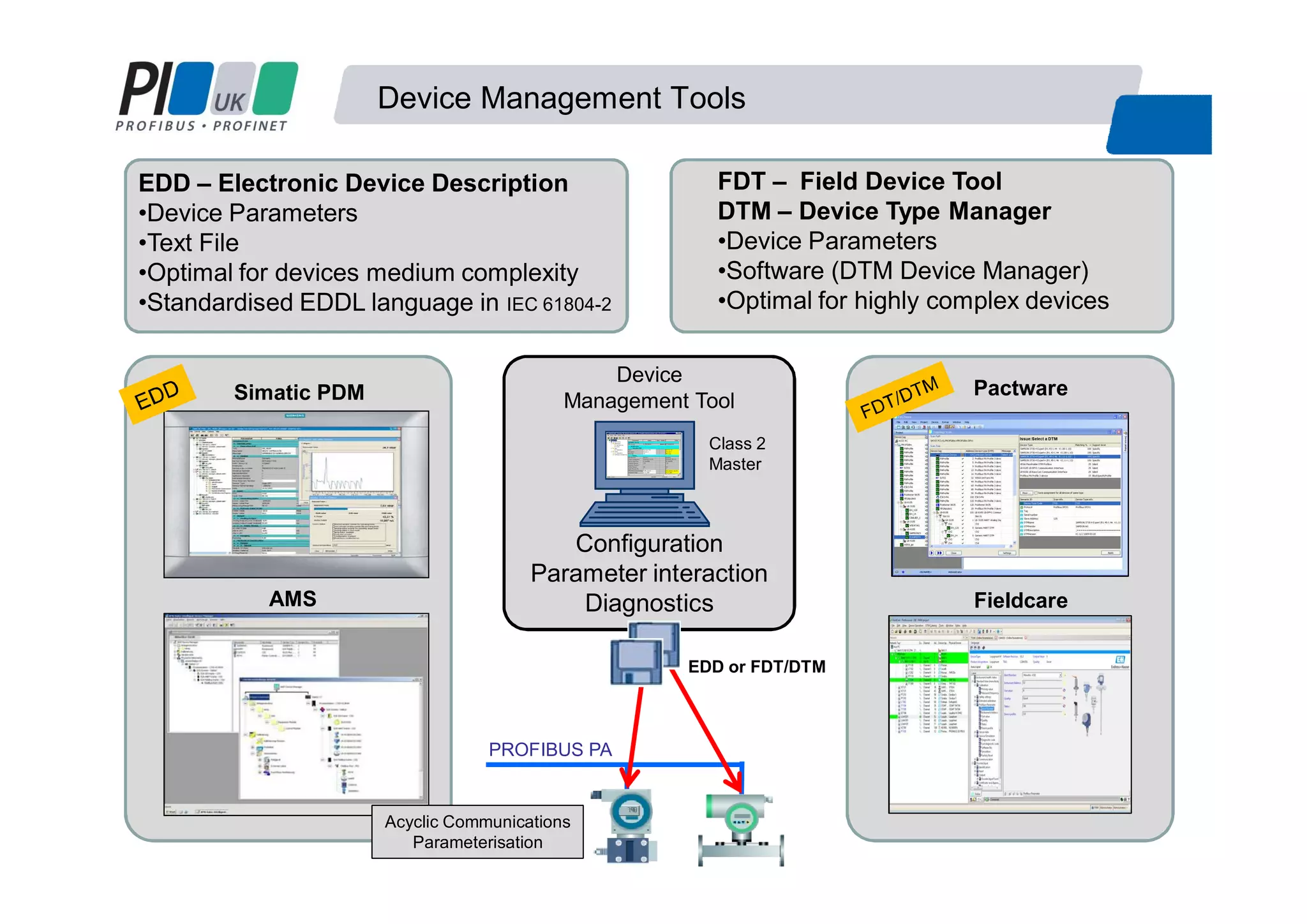

This document summarizes a presentation on setting up Profibus PA networks. It discusses what Profibus PA is, the benefits of using a fieldbus network, the key system components, and rules for configuring a Profibus PA network. The presentation covered topics such as what comprises a Profibus PA network, how to add and remove devices, and tools for configuring and managing devices. It concluded with a live demonstration of network configuration using tools like Pactware and Simatic PDM.