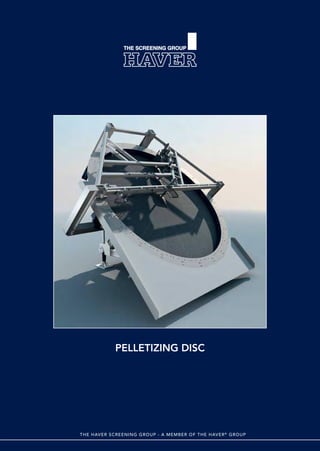

Pelletizing discs

- 1. PELLETIZING DISC THE HAVER SCREENING GROUP - A MEMBER OF THE HAVER ® GROUP

- 2. HAVER® PELLETIZING DISCS Pelletizing Process row grain size distribution ranging dolomite, bentonite and coal dust. The pelletizing process allows between 9 mm and 15 mm. The raw These micro pellets are fed into a sin- the formation of ore, fertilizer, material in the process consists of ter machine to produce sinter cake, chemicals, biomass, animal iron ore (< 100 μm), binders (i.e. ben- which is then broken down and compound feed, color pig- tonite) and additives such as coal smelted in a blast furnace. ments and other products into dust. The moisture of the raw mate- a ball-shaped format. THE rial can be variable. The segregation effect of the HAVER SCREENING GROUP HAVER® PELLETIZING DISC guaran- (HSG) offers custom made Hybrid Pelletized Sinter (HPS) tees a continuous narrow grain size pelletizing discs with a size of HPS is characterized by micro pellets distribution in the desired size range 7500 mm in diameter and feed- with high mechanical strength, meas- and a minimal recycling rate. In com- ing capacities up to 150 t/h. uring between 2 mm and 8 mm. HPS parison to a drum with a recycling feed consists of iron ore pellet feed rate of app. 100 % to 400 %, the rate Iron ore pellet feed fines (PFF) fines (PFF), return fines and iron and is extremely low. The specific energy The iron ore pelletizing process is steel work remnants, filter dust, addi- consumption of a disc is < 1.0 kWh / t marked by spherical pellets in a nar- tives and binders like limestone, (iron ore pellets). Bonding forces in pellets growing Loose agglomerate Liquid Particle Liquid Abrasion Nucleation Accretion transition Liquid Particle Particle Compacted Boundary layer agglomerate Air inclusion Coalescence Flake Abrasion transition Densification Principle of agglomeration

- 3. 2|3 Technical Information ing operation. The disc’s rotary speed matically. The pelletizing discs are HAVER® PELLETIZING DISCS are is also adjustable. Due to the sophis- equipped with static scrapers to en- maintenance friendly due to their ticated drive design, it is possible to able constant material layering with rugged design, allowing a high pro- start the disc fully loaded. To influ- variable height. Long operating life- ductivity. The inclination angle of the ence the product quality and to meet times are ensured by autogenous via disc can be adjusted automatically changing operation conditions the protection. via a motor driven spindle, even dur- side wall height is adjustable auto- Technical Details ■ Inside diameter: 7500 mm ■ Installed power: 185 - 255 kW ■ Disc wall height: 560 - 900 mm ■ Total weight: 55 tons ■ Rotation speed: 1 - 10 rpm ■ Feeding capacity: 0 - 150 t/h ■ Inclination angle: 45 - 60° ■ Specific capacity: 2 - 3 t/m²h (iron ore) THE HAVER SCREENING GROUP - A MEMBER OF THE HAVER ® GROUP

- 4. HAVER® PELLETIZING DISCS HAVER® PELLETIZING DISCS are parameters such as disc inclination, power blackouts or emergency stops. composed mainly of the support disc speed and side wall height. The frequency converter enables a frame, the base frame with a for- HAVER® PELLETIZING DISCS offer continuous drive speed control and ward pivot support to hold the disc the adjustment of these parameters the automatic inclination allows a and the scrapers. manually or automatically during op- continuously variable adjustment eration. The disc inclination angle can while the disc is running. The central All scrapers are installed at the top be varied through an adjustment lubrication system supplies all greas- frame of the disc. They are extremely spindle between the base frame and ing points of the disc automatically. robust and are coated with innovative the upright support columns. No further service is necessary. wear protection material. The scrap- The disc itself is supported on a ers reach into the process room to rotating assembly. The triangular The water spray system is adaptable to prepare a base layer of fine material arrangement of the support frame, the product needs and to moisturize on the bottom of the disc. Further- disc and inclination adjustment allows the nuclei zone in the disc to obtain more, in order to meet the cus- an inclination pivot point that is up the optimum agglomeration results. tomer's requirements, each scraper's close to the pellet discharge. A flexi- Compared to a pelletizing drum, a pel- height adjustment feature allows for ble discharge chute at the pellet letizing disc offers a greater range of an adjustment of the layer thickness discharge is installed at the upright variable setting options as well as com- at the bottom. This autogenous wear support columns underneath the plete flexibility in regards to: protection guarantees an extended rotating disc, and adjusts to match ■ Drive speed life time and trouble-free operation. the inclination angle of the disc. ■ Inclination Due to the adjustable angles of the The drive system and frequency ■ Side wall height disc’s scrapers, an optimal material converter make a fully loaded start- ■ Water rate flow can be realized. up possible while preventing ■ Water spray point The granulometry of the pellet pro- damages to shaft and slewing bear- ■ Feed point ducts are influenced by several ing in case of abrupt disc stops, ■ Feed rate Thickener Storage bins for iron o Iron ore slurry from concentration plant limestone, coal, bento Dewatering e.g. disc filter Storage tank Recycling ro Waste water Roller mill Pellet feed fines < 63 μm Sedimentation basin

- 5. 4|5 ore concentrate, nite Intensive mixer Furnace oute HAVER® screening machine Fluid binding agent e. g. water HAVER® pelletizing disc Basic flow sheet of a pelletizing plant Roller screen Product: Iron ore pellets Over flow Product Stockpile Over and under flow THE HAVER SCREENING GROUP - A MEMBER OF THE HAVER ® GROUP

- 6. HAVER® PELLETIZING DISCS Advantages: ■ Heavy-duty construction ■ Flexible operation - starting under full load - stepless drive speed control during operation - side wall height adjustment during operation - inclination adjustment during operation - autogenous wear protection - narrow particle size distribution and minimum recirculation load - low specific energy consumption of approx.< 1.0 kWh / t (iron ore) ■ Vibration free operation ■ Precise rotation ■ Bottom and side wall scrapers (metal or ceramic) ■ Flexible water spray system ■ Central lubrication

- 7. 6|7 RESEARCH AND DEVELOPMENT HAVER ENGINEERING Meißen (HEM) HEM provides: ■ Pellet analysis in accordance with is a subsidiary of HAVER & BOECKER, ■ Test facilities for agglomeration international standards located in Meißen, Germany. HEM is processes, including 400 mm and ■ Screening studies an associated institute of the 1000 mm pelletizing discs, mixers, ■ Dimensioning studies Technical University Bergakademie dosing equipment and moisture ■ Basic engineering Freiberg, the oldest and most measurement - custom-made process solutions renowned scientific mining and ore ■ Material characterization - research and development for university in the world. - chemical individual customer requirements - physical - mineralogical THE HAVER SCREENING GROUP - A MEMBER OF THE HAVER ® GROUP

- 8. THE HAVER SCREENING GROUP Additional representatives worldwide! Brazil Germany India HAVER & BOECKER HAVER ENGINEERING HAVER IBAU INDIA Latinoamericana Máqs. Ltda. Poststraße 1 Baroda-Halol Road Rod. Campinas Monte Mor, km 20 01662 Meißen Khandiwada, Post Asoj 13190 MONTE MOR S.P. Phone: +49-(0)3521-409399-0 District Vadodara – 391 510 Phone: +55-19-3879-9100 Telefax: +49-(0)3521-409399-20 Phone: +91 2676 306600 Telefax: +55-19-3879-1410 E-mail: hem@haverboecker.com Telefax: +91 2676 306699 E-mail: haverhbl@haverbrasil.com.br Internet: www.haverengineering.de E-mail: info@haveribauindia.com Internet: www.haverbrasil.com.br Internet: www.haveribauindia.com HAVER & BOECKER Canada DIE DRAHTWEBER China Ennigerloher Straße W.S. TYLER 59302 Oelde HAVER IBAU SHENZHEN 225 Ontario Street Phone: +49-(0)25 22-300 1st Floor, L BuildingJingtie Technological P.O. Box 3006 Telefax: +49-(0)25 22-30 403 & Industrial Zone No. 49 Changjiangpu St. Catharines, Ontario L2R 7B6 E-mail: dw@haverboecker.com Road Heao Village Henggang Town Phone: +1-905-688-2644 Internet: www.weavingideas.com Longgang District SHENZHEN 518115 The machines and plants shown in this leaflet as well as the stated technical parameters are examples of customer-specific technical solutions. Therefore they are subject to modifications. The designation ® indicates a registered trademark of HAVER & BOECKER OHG in Germany. Several indicated designations are registered trademarks also in other countries worldwide. Telefax: +1-905-688-4733 Phone: +86 – 755 2862 5372 E-mail: wstsales@wstyler.on.ca Mexico Telefax: +86 – 755 2862 5382 Internet: www.wstyler.ca E-mail: info@haveribau.cn HAVER & BOECKER MEXICANA Internet: www.haveribau.cn Germany Av. Paseo de la Reforma no. 195 piso 7, Oficina 13-B. HAVER & BOECKER CP. 06500 Mexico, D.F. MACHINERY DIVISION MÜNSTER Phone: +52 55 5566.9964 Robert-Bosch-Straße Telefax: +52 55 5566.9527 48153 Münster E-mail: jpatino@havermexicana.com.mx Phone: +49-251-9793-0 tycan@prodigy.net.mx Telefax: +49-251-9793-156 Internet: www.havermexicana.com.mx E-mail: niagara@haverboecker.com Internet: www.haverboecker.com Poland HAVER TRADING Ul. Kolejowa 3 Bielany Wroclawskie 55-040 Kobierzyce Phone: 0048 71 7960204 Telefax: 0048 71 7960205 E-mail: htr@haverboecker.com Internet: www.havertrading.pl Russia HAVER & BOECKER Russia Gostinichny Proezd, 8, bld.1, office 46 127106 MOSCOW Phone/Telefax: +7 495 7833448 E-mail: m.maslova@haverrussia.ru Internet: www.haverrussia.ru South Africa HAVER SOUTHERN AFRICA Unit 4 , Sunpark 178 Smit Street, Fairland Johannesburg 2195 Phone: +27 - 11 - 476 - 4804 E-mail: southernafrica@haverboecker.com Internet: www.HaverScreeningGroup.co.za Switzerland HAVER SUISSE Oberdorf 16, Postfach 27 PM 279 E 3007 0410 1,5 Fe CH-5707 Seengen Phone: +62-767 77 77 Telefax: +62-767 77 67 E-mail: info@haversuisse.ch