Ndt Weld RepairCSWIP.pdf

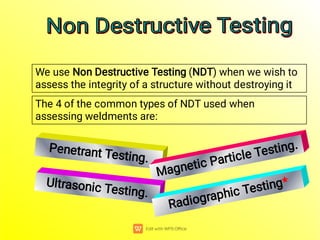

- 1. The 4 of the common types of NDT used when assessing weldments are: Penetrant Testing. We use Non Destructive Testing (NDT) when we wish to assess the integrity of a structure without destroying it Magnetic Particle Testing. Ultrasonic Testing. Radiographic Testing* Non Destructive Testing Non Destructive Testing Non Destructive Testing Non Destructive Testing

- 2. Two types of penetrants are: Colour contrast Fluorescent Penetrant Colour contrast Fluorescent Penetrant 1) Colour contrast 2) Fluorescent Penetrant* Any penetrant that has been drawn into a crack by capillary action will be drawn out into the developer* Once the contact time has elapsed, the penetrant is removed and a developer is then applied* First the work must be cleaned thoroughly, then a penetrant is applied for a specified time* Penetrant Testing Penetrant Testing Penetrant Testing Penetrant Testing Procedure

- 3. Apply Penetrant Clean then apply Developer Result* Method Colour Contrast Penetrant Colour Contrast Penetrant Colour Contrast Penetrant Colour Contrast Penetrant

- 4. Advantages Disadvantages 4) Simple equipment 4) No permanent record* 3) Extremely messy 2) Surface flaws only 1) Highly clean metal 3) Low cost method 2) All materials (Non Porous) 1) Low operator skill level Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages

- 5. 1) Wet ink 2) Dry powder 3) Fluorescent ink 1) Wet ink 2) Dry powder 3) Fluorescent ink 1) Wet ink 2) Dry powder 3) Fluorescent ink 1) Wet ink 2) Dry powder 3) Fluorescent ink 1) Wet ink 2) Dry powder 3) Fluorescent ink 1) Wet ink 2) Dry powder 3) Fluorescent ink The types of magnetic media used are: 1) Wet ink 2) Dry powder 3) Fluorescent ink* The weld length must be crossed at 90° by the magnetic field* A magnetic ink is applied which will concentrate in areas of flux leakage, as those caused by flaws* First the work must be cleaned and a whitener applied for contrast. A magnetic flux is then applied by permanent magnet, electro magnet, or straight current* Procedure Magnetic Particle Testing Magnetic Particle Testing Magnetic Particle Testing Magnetic Particle Testing

- 6. Contrast paint Magnet & Ink Method Result* Magnetic Particle Testing Magnetic Particle Testing Magnetic Particle Testing Magnetic Particle Testing

- 7. 4) No permanent record* Advantages Disadvantages 4) Simple equipment 3) Can cause arc strikes # 2) De-magnetize after use 1) Fe Magnetic metal only 3) Relatively cheap 2) Sub surface flaws 1) Low operator skill level Advantages and Disadvantages Advantages and Disadvantages # When using the straight current prod technique

- 8. Procedure Any imperfections will rebound the sound waves causing a signal to occur on the cathode ray tube* A probe is then applied with the correct angle for the weld preparation and sound waves are transmitted* First the work must be cleaned thoroughly, then a couplant is applied to increase sound transmission* Ultrasonic Testing Ultrasonic Testing Ultrasonic Testing Ultrasonic Testing

- 9. Apply Couplant Sound wave Signal rebounded from Lack of fusion Signal rebounded from Lack of fusion Signal rebounded from Lack of fusion Signal rebounded from Lack of fusion CRT display Method Result* Ultrasonic Testing Ultrasonic Testing Ultrasonic Testing Ultrasonic Testing

- 10. Advantages Disadvantages 4) Portable/instant results 4) No permanent record* 3) Requires calibration 2) Difficult to interpret 1) High operator skill 3) No safety requirements 2) Most materials 1) Can find lack of fusion Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages

- 11. The 2 types of radiation used in industrial radiography: 1) X rays (from Cathode Ray Tube) 2) Gamma rays (from a Radioactive Isotope)* Any imperfections in line with the beam of radiation will be shown on the film after exposure and development* A film is placed inside a cassette between lead screens. It is then placed to the rear of the object to be radiographed A radiographic source, is exposed to the work and film for a pre-calculated time* Procedure Radiographic Testing Radiographic Testing Radiographic Testing Radiographic Testing

- 12. Radioactive source Method Film cassette Load film Exposure to Radiation Interpret Graph IQI Develope d Graph Latent image on the film Radiographic Testing Radiographic Testing Radiographic Testing Radiographic Testing

- 13. Advantages Disadvantages 4) Gamma ray is portable 4) Safety requirements* 3) Lack of sidewall fusion 2) Difficult interpretation 1) High operator skill 3) Assess root pen’ in pipe 2) Most materials 1) A permanent record ? Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages Advantages and Disadvantages

- 14. New TWI Video “Non Destructive Testing” 30 Minutes Non Destructive Testing Non Destructive Testing Non Destructive Testing Non Destructive Testing

- 15. Coffee Break Coffee Break Coffee Break Coffee Break

- 16. Weld Repairs Weld Repairs Weld Repairs Weld Repairs Weld Repairs: Weld repairs can be divided into two specific areas: 1) Production repairs 2) In service repairs* Production repairs are usually identified by the Welding Inspector, or NDT operator during the process of inspection, or evaluation of reports to the code, or applied standard*

- 17. Weld Repairs Weld Repairs Weld Repairs Weld Repairs A typical defect is shown below: * Prior to repair the defect may need to undergo the following: 1) A defect analysis and report 2) An assessment of defect extremity 3) An excavation procedure 4) NDT procedures 5) A welding repair procedure 6) Welder approval to the approved repair procedure 7) Any subsequent treatments procedures i.e. PWHT *

- 18. Plan View of defect with drilled ends Side View of defect excavation* Completed repair* Weld Repairs Weld Repairs Weld Repairs Weld Repairs *

- 19. NDT confirmation of successful repair: After the excavation has been filled the weldment should then be undergo a complete retest using NDT to ensure no further defects have been introduced by the repair. NDT may also need to be further applied after any additional post weld heat treatment has been carried out* Weld Repairs Weld Repairs Weld Repairs Weld Repairs

- 20. Residual welding stresses are defined as those stresses that remain inside a material after welding has been carried out Stresses are caused by the heat of welding, which produces local expansion and contraction to take place If a metal was heated & cooled uniformly no stresses would remain, as expansion & contraction would be uniform Welding causes only local heating and cooling conditions to exist, hence some residual stresses to remain in the metal* Residual Stress & Distortion Residual Stress & Distortion Residual Stress & Distortion Residual Stress & Distortion

- 21. Residual stresses can have very complex patterns in welded constructions. In simple butt welded plates they may be indicated as shown below: Compressive Tensile Tensile Directions of Welding Related Stresses Directions of Welding Related Stresses Directions of Welding Related Stresses Directions of Welding Related Stresses *

- 22. Longitudinal Transverse Short transverse Plan View of plate End View of plate Weld We can say that expansion/contraction has three directions. Directions of Expansion/Contraction Directions of Expansion/Contraction Directions of Expansion/Contraction Directions of Expansion/Contraction

- 23. One effect of welding related stresses is distortion Distortion is the movement of material in one area caused by expansion and contraction, and local elastic/ plastic movement that misshapes the component* The various types of distortion produced are caused by the directions and amount of expansion and contractional stresses involved, and the ability of the material to resist the stress without the formation of elastic/plastic strain, or deformation It is this deformation that produces distortion in a product* Effects of Expansion/Contraction Effects of Expansion/Contraction Effects of Expansion/Contraction Effects of Expansion/Contraction

- 24. Distortion* Angular Transverse distortion Longitudinal distortion Effects of Expansion/Contraction Effects of Expansion/Contraction Effects of Expansion/Contraction Effects of Expansion/Contraction

- 25. The volume of weld metal in a joint will also effect the amount of local expansion and contraction Hence the more volume of weld metal then the overall amount of distortion will be higher* Effects of Weld Volume on Distortion Effects of Weld Volume on Distortion Effects of Weld Volume on Distortion Effects of Weld Volume on Distortion

- 26. Many methods are used to control the effects of distortion. Perhaps the best of these is to to pre set the materials to allow distortion to bring it to its final shape. This method is called offsetting, or pre-setting* a) Practical b) Practical c) Impractical* Control of Distortion Control of Distortion Control of Distortion Control of Distortion

- 27. Other forms of distortion control stop the movement of material from occurring by using such methods as clamping, jigging, strong backs, and tacking etc* Back-step & balance welding are sequences which may also be used to control the effects of distortion* These methods will reduce the distortion, but will also amass the maximum amount of residual stresses to exist* Control of Distortion Control of Distortion Control of Distortion Control of Distortion

- 28. 1) Heating 2) Soaking 3) Cooling Temp Time 1 2 3 All heat treatments applied to metals are cycles of 3 elements. Heat Treatments Heat Treatments Heat Treatments Heat Treatments

- 29. Annealing: Used to make metals soft and ductile For steels, the component is heated above its UCT, or upper critical temperature, soaked for 1 hour/25mm of thickness and left in the furnace to cool Produces a coarse grain structure & low toughness* Normalising: Used to make steels tough As for annealing, but the steel is removed from the furnace after soaking to cool in still air Produces a fine grain structure with good toughness* Heat Treatments Heat Treatments Heat Treatments Heat Treatments

- 30. Hardening: Used to make some steels harder Used to increase the hardness of some plain carbon & alloy steels. Plain carbon > 0.3% The cycle is the same as previously but the cooling is rapid i.e. Quenched in water, oil, but sometimes air* Tempering: Used after hardening to balance the properties of Toughness & Hardness The temperature range is from 220 – 723 °C The cooling part of the cycle should not be too rapid, but over heating will over temper the steel* Heat Treatments Heat Treatments Heat Treatments Heat Treatments

- 31. Used after welding to release residual stresses, caused by welding operations* By heating the steel, the yield point is suppressed/reduced relieving residual stresses as plastic strain at a much lower level of stress* Force/Stress required to induce plastic strain* The effect of heat on the position of the yield point* Stres s Strain PWHT: Y Heat Treatments Heat Treatments Heat Treatments Heat Treatments

- 32. Pre-Heating: Used mainly on steels to retard the cooling rate of a hardenable steel and reduce the hardening effect (Martensite formation) Is also used to help diffusion of Hydrogen from the HAZ of hardenable steels to avoid hydrogen cracking. Typically < 350 °C Is also used to produce a more uniform rate of cooling, and control distortion, or effects of high contractional strains* Heat Treatments Heat Treatments Heat Treatments Heat Treatments

- 33. Gas Welding & Cutting Gas Welding & Cutting Gas Welding & Cutting Gas Welding & Cutting *

- 34. Neutral Name Pictorial view Uses Fusion welding most metals. Flame temp > 3,200 °C* Oxidising Bronze Welding* Carburising Hard surfacing & fusion & Brazing Aluminium & alloys* Gas Welding & Cutting Gas Welding & Cutting Gas Welding & Cutting Gas Welding & Cutting

- 35. A jet of pure oxygen reacts with high temperature iron (>1100 C) to produce Fe3 O4 by exothermic reaction. This dross is then removed by the pressure of the oxygen jet* Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Different types of fuel gases may be used for the pre- heating flame in oxy fuel gas cutting: i.e. Acetylene. Hydrogen. Propane. Etc* By adding Iron powder to the flame we are able to cut most metals “Iron Powder Injection”* The high intensity of heat and rapid cooling will cause hardening in low alloy, and medium, or high C steels They are thus pre-heated to avoid the hardening effect*

- 36. Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Oxy/Fuel Gas Cutting Slightly rounded top edge caused by too close a nozzle gap 50m m The “Kerf” Flutes

- 37. MMA electrodes are specially produced for cutting and gouging. Oxy/Arc and Arc/Air are arc cutting process that produce lots of fume and arc air produce a high noise level. All these processes require good extraction, and ear protection is vital for arc/air Both oxy arc and arc air use special types of electrodes and gas supplies, which will be described by the course lecturer* Arc Cutting Processes Arc Cutting Processes Arc Cutting Processes Arc Cutting Processes

- 38. Safety is the responsibility everyone. As respected officers, it is the duty of all welding inspectors to ensure that safe working practices are strictly followed. Safety in welding can be divided into several areas, some of which are as follows: (Areas to be expanded briefly by the lecturer/ presenter) 1) Welding/cutting process safety.* 2) Electrical safety.* 3) Welding fumes & gases. Use & storage of gases.* 4) Safe use of lifting equipment.* 5) Safe use of hand tools and grinding machines.* Safety in Welding Operations Safety in Welding Operations Safety in Welding Operations Safety in Welding Operations

- 39. 1) 2) 3) 4) 5) The hazards of infra red and/or ultra violet light The hazards of heat, burns and fire The hazards of toxic and non toxic gases from process, coatings, or purging, and gases stored at high pressure The hazards of working with high voltages & currents The hazards of working in confined spaces* Careful consideration should be given to safety hazards when using a particular welding process. This may include:* Welding Process Safety Welding Process Safety Welding Process Safety Welding Process Safety

- 40. 1) 2) 3) 4) 5) 6) Removing any combustible materials from the area Checking all containers to be cut are fume free and have a Permit to Work Providing ventilation and extraction where required Ensuring good gas safety is being practised Keeping oil and grease away from oxygen Using ear defenders when arc air cutting Careful consideration should be given to safety when using gas, or arc cutting systems by:* Cutting Process Safety Cutting Process Safety Cutting Process Safety Cutting Process Safety

- 41. Safe working with electrical power is mostly common sense. Ensure that insulation is used where required and that cables and connections are in good condition. (Check the duty cycle)* Gases should be stored separately, and cylinders should be secured when used in the vertical position, especially oxygen* Exposure to dangerous welding fumes and gases from electrodes, plating, i.e.ozone, nitrous oxide, phosgene, cadmium, beryllium are to name just a few. Always use extraction/breathing systems. If in any doubt, stop the work* General Safety General Safety General Safety General Safety

- 42. From the points that have been covered in the safety lecture, and/or the Video, complete the safety check list exercise in your course text* General Welding Safety General Welding Safety General Welding Safety General Welding Safety

- 43. “Weldability” is a term used in welding engineering to describe the ease of which a material can be welded by the common welding processes and still retain the properties for which it was designed* If we say that a material has limited weldability, it means that we need to take special measures to ensure that the properties as required are maintained* Most materials are weldable with certain processes. weldability weldability The weldability of steel is mainly dependant on carbon content & alloying, though most steels have a degree of weldability* The Weldability of Steels The Weldability of Steels The Weldability of Steels The Weldability of Steels

- 44. 1) Hydrogen induced HAZ cracking in Low Alloy Steels 1) Hydrogen induced HAZ cracking in Low Alloy Steels 1) Hydrogen induced HAZ cracking in Low Alloy Steels 2) Hydrogen weld metal cracking in Micro Alloy Steels 2) Hydrogen weld metal cracking in Micro Alloy Steels 2) Hydrogen weld metal cracking in Micro Alloy Steels 3) Solidification cracking in Ferritic steels 3) Solidification cracking in Ferritic steels 3) Solidification cracking in Ferritic steels 3) Solidification cracking in Ferritic steels 4) Lamellar tearing in Ferritic steels 4) Lamellar tearing in Ferritic steels 5) Inter-granular corrosion in Stainless Steels* 5) Inter-granular corrosion in Stainless Steels* 5) Inter-granular corrosion in Stainless Steels* The Weldability of Steels for CSWIP 3.1 The Weldability of Steels for CSWIP 3.1 The Weldability of Steels for CSWIP 3.1 The Weldability of Steels for CSWIP 3.1

- 45. Plain carbon steels contain only iron & carbon as main alloying elements, traces of Mn Si Al S & P may also be present* 3) High Carbon Steel 0.6 – 1.4% Carbon* 2) Medium Carbon Steel 0.3 – 0.6% Carbon* 1) Low Carbon Steel 0.01 – 0.3% Carbon* Plain Carbon Steels:* Steels are classified into groups as follows:* Classification of Steels Classification of Steels Classification of Steels Classification of Steels

- 46. An Alloy steel is one that contains more than Iron & Carbon as a main alloying elements* Alloy steels are divided into 2 groups:* Low Alloy Steels< 7% extra alloying elements High Alloy Steels> 7% extra alloying elements Classification of Steels Classification of Steels Classification of Steels Classification of Steels * *

- 47. Iron is an element that can exist in 2 types of cubic structures, depending on the temperature. This is an important feature* A most important function in the metallurgy of steels, is the ability of iron to dissolve carbon in solution* The carbon atom is very much smaller than the iron atom and does not replace it in the atomic structure, but fits between it* Iron atoms Carbon atoms* Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels The following basic foundation information on metallurgy will not form any part of your CSWIP examination*

- 48. α Alpha iron This structure occurs below 723 °C and is body centred, or BCC in structure It can only dissolve up to 0.02% Carbon Also known as Ferrite or BCC iron* At temperatures below Ac/r 1, (LCT) iron exists like this* Compressed representation could appear like this Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels *

- 49. γ Gamma iron This structure occurs above the UCT in Plain Carbon Steels and is FCC in structure. It can dissolve up 2.06% Carbon Also called Austenite or FCC iron* At temperatures above the Ac/r 3, (UCT) iron exists like this* Compressed representation could appear like this Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels *

- 50. If steel is heated and then cooled slowly in equilibrium, then exact reverse atomic changes take place* If a steel that contains more than 0.3% Carbon is cooled quickly, then the carbon does not have time to diffuse out of solution, hence trapping the carbon in the BCC form of iron. This now distorts the cube to an irregular cube, or tetragon* This supersaturated solution is called Martensite and is the hardest structure that can be produced in steels* Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels

- 51. Martensite can be defined as: A supersaturated solution of carbon in BCT iron (Body Centred Tetragonal) It is the hardest structure we can produce in steels* Compressed representation could appear like this Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels Basic Atomic Structure of Steels If some steels are cooled quickly their structure looks like this* *

- 52. Ferrite: Low carbon solubility. Maximum 0.02%* Austenite: High carbon solubility. Maximum 2.06%* Solubility of Carbon in BCC & FCC phases of steels* Martensite: The hardest phase in steels, which is produced by rapid cooling from the Austenite phase It mainly occurs below 300 °C* TheImportant Points of Steel Microstructures TheImportant Points of Steel Microstructures TheImportant Points of Steel Microstructures TheImportant Points of Steel Microstructures

- 53. The atomic structures of plain carbon steels have been briefly identified and explained in this lecture* To summarize the effect of increasing the hardness of steels by thermal treatment, it can be said that the formation of Martensite is caused by the entrapment of carbon in solution, produced by rapid cooling from temperatures above the Upper Critical* In plain carbon steels there must be sufficient carbon to trap. In low alloy steels however, the alloying elements play a significant part in the thermal hardening of steels* Summary of Steel Microstructures Summary of Steel Microstructures Summary of Steel Microstructures Summary of Steel Microstructures

- 54. Crack type: H² HAZ & weld metal cracking Location: a. HAZ (Longitudinal) b. Weld metal (Transverse) Steel types: a. All hardenable steels including: b. HSLA steels c. Quench & Tempered steels Microstructure: Martensite* Occurs when: Hydrogen is above 15 ml/100 gm weld metal Hardness is above 350 VPN Stress is greater than 0.5 of the yield stress Temperature is below 300 ºC* Hydrogen Induced Cracking Hydrogen Induced Cracking Hydrogen Induced Cracking Hydrogen Induced Cracking

- 55. Hydrogen absorbed in a long, or unstable arc Hydrogen produced from oil, or paint on plate Cellulosic electrodes produce hydrogen as a shielding gas Hydrogen crack Hydrogen crack Martensite forms from γ H2 diffuses to γ in HAZ* H2 H2 Hydrogen Induced Cracking Hydrogen Induced Cracking Hydrogen Induced Cracking Hydrogen Induced Cracking

- 56. To find a simple method we would need to look at the effect of increasing carbon content on the properties of iron* It is however important to match the strength of the weld to the strength of the plate, and so a simple way of matching weld strength must be found and utilised* Typically the level of alloying is in the region of 0.05% and elements such as vanadium molybdenum and titanium. are used. It would be impossible to match this micro alloying in the electrode due to the effect of losses across an electric arc* HSLA or Micro-Alloyed Steels are high strength steels that derive their high strength from finite alloying* Hydrogen Induced Cracking in HSLA Steels Hydrogen Induced Cracking in HSLA Steels Hydrogen Induced Cracking in HSLA Steels Hydrogen Induced Cracking in HSLA Steels

- 57. Ductility Hardness Tensile Strength 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.4 1.6 % Carbon 0.83 % Carbon (Eutectoid)* Increasing the carbon content will increase the strength, but will also increase greatly the formation of martensite in the weld. This may now produce H2 Cracks across weld* Effects of Carbon on the Properties of Iron Effects of Carbon on the Properties of Iron Effects of Carbon on the Properties of Iron Effects of Carbon on the Properties of Iron

- 58. Transverse Weld Cracks in HSLA Steels* Longitudinal contractional strain Low ductility weld metal H2 HAZ Cracks in Alloy steels* Hydrogen Induced Cracking Steels Hydrogen Induced Cracking Steels Hydrogen Induced Cracking Steels Hydrogen Induced Cracking Steels

- 59. 6) Avoid any restraint, and use high ductility weld metal* 5) Carry out any specified PWHT as soon as possible* 4) Remove any paint, oil or moisture from the plate or pipe* “ ” “ ” 3) If using a cellulosic E 6010 for the root run, insert the “Hot pass” as soon as possible. (Before HAZ < 300 °C)* 2) Use Low Hydrogen processes with short arcs & ensure consumables are correctly baked & stored as required* 1) Maintain calculated preheats, and never allow the inter-pass temperature to go below the pre-heat value* Prevention of Hydrogen Induced Cracking Prevention of Hydrogen Induced Cracking Prevention of Hydrogen Induced Cracking Prevention of Hydrogen Induced Cracking

- 60. Crack type: Solidification cracking Location: Weld centre (longitudinal) Steel types: High sulphur & phosphorus steels. Microstructure: Columnar grains In direction of solidification* Occurs when: Liquid iron sulphides are formed around solidifying grains. High contractional strains are present High dilution processes are being used. There is a high carbon content in the weld metal* Solidification Cracking Fe Steels Solidification Cracking Fe Steels Solidification Cracking Fe Steels Solidification Cracking Fe Steels

- 61. 1) The first steps in eliminating this problem would be to choose a low dilution process, and change the joint design* 2) Grind and seal in any lamination and avoid further dilution* 3) Add Manganese to the electrode to form spherical Mn/S which form between the grain and maintain grain cohesion* 4) As carbon increases the Mn/S ratio required increases exponentially and is a major factor. Carbon content % should be a minimised by careful control in electrode and dilution* 5) Limit the heat input, hence low contraction, & minimise restraint* Control of Solidification Cracking Control of Solidification Cracking Control of Solidification Cracking Control of Solidification Cracking

- 62. Liquid Iron Sulphide films Solidification crack Contractional strain Solidification Cracking Fe Steels Solidification Cracking Fe Steels Solidification Cracking Fe Steels Solidification Cracking Fe Steels *

- 63. Spherical Mn Sulphide balls form between solidified grains Cohesion and strength between grains remains Contractional strain Prevention of Solidification Cracking Prevention of Solidification Cracking Prevention of Solidification Cracking Prevention of Solidification Cracking * Add Manganese to weld metal

- 64. Crack type: Lamellar tearing Location: Below weld HAZ Steel types: High sulphur & phosphorous steels Microstructure: Lamination & Segregation* Occurs when: High contractional strains are through the short transverse direction. There is a high sulfur content in the base metal. There is low through thickness ductility in the base metal. There is high restraint on the work* Lamellar Tearing Lamellar Tearing Lamellar Tearing Lamellar Tearing

- 65. High contractional strains Lamellar tear Restraint Lamellar Tearing Lamellar Tearing Lamellar Tearing Lamellar Tearing

- 66. Plate to be tested* Full fusion compound welded cruciform joint* Machined test piece* The test piece is machined from the cruciform joint and placed under tension. If Lamellar tearing was present it would fail at a low value* Contractional strain* Testing for Lamellar Tearing Testing for Lamellar Tearing Testing for Lamellar Tearing Testing for Lamellar Tearing Through thickness tensile test*

- 67. • • • • • Assessment of susceptibility to Lamellar Tearing: Carry out through thickness tensile test Carry out cruciform welded tensile test Carry out Ultra-sonic testing Carry out penetrant testing of plate edges Carry out full chemical analysis (S < 0.05%)* CheckingforLamellarTearingSusceptability CheckingforLamellarTearingSusceptability CheckingforLamellarTearingSusceptability CheckingforLamellarTearingSusceptability

- 68. Methods of avoiding Lamellar Tearing:* Control of Lamellar Tearing Control of Lamellar Tearing Control of Lamellar Tearing Control of Lamellar Tearing 1) Avoid restraint* 2) Use controlled low sulfur plate * 3) Grind out surface and butter * 4) Change joint design * 5) Use a forged T piece (Critical Applications)*

- 69. Re-design weld* Grind and infill with ductile weld metal* Control restraint* For critical work a forged T piece may be used* Forged T Piece Control of Lamellar Tearing Control of Lamellar Tearing Control of Lamellar Tearing Control of Lamellar Tearing

- 70. Crack type: Inter-granular corrosion Location: Weld HAZ. (longitudinal) Steel types: Stainless steels Microstructure: Sensitised grain boundaries* Occurs when: An area in the HAZ has been sensitised by the formation of chromium carbides. This area is in the form of a line running parallel to and on both sides of the weld. This depletion of chromium will leave the effected grains low in chromium oxide which is what produces the corrosion resisting effect of stainless steels. If left untreated corrosion and failure will be rapid* Intergranular Corrosion Intergranular Corrosion Intergranular Corrosion Intergranular Corrosion

- 71. During the welding of stainless steels, a small grain area in the HAZ, parallel to the weld will form chromium carbide at the grain boundaries. This depletes this grain of the corrosion resisting chrome oxide We say that the steel has become “Sensitised” or has become sensitive to corrosion* Intergranular Corrosion Intergranular Corrosion Intergranular Corrosion Intergranular Corrosion

- 72. 3) A sensitised Stainless Steel may be de-sensitised by heating it to above 1100 °C where the Chrome carbide will be dissolved. The steel is normally quenched from this temperature to stop re- association* Control of Intergranular Corrosion Control of Intergranular Corrosion Control of Intergranular Corrosion Control of Intergranular Corrosion 1) Use Stabilised Stainless Steels* 2) Use Low Carbon Stainless Steels ( Below .04%)*

- 73. Attempt the end of course Multi Choice question paper answering 30 questions Time allowed 30 minutes Attempt the specific question paper answering 4 from 6 questions Time allowed 1 hour WIS 5 E Only End of Course Examination End of Course Examination End of Course Examination End of Course Examination

- 74. Practice observing & reporting using the pipes or plates and forms provided Use your nominated pipe code for all your visual inspections. Practice this up and till the end of the day, or as directed by your course lecturer* WIS 5 Only Practical Inspection Practice Practical Inspection Practice Practical Inspection Practice Practical Inspection Practice