Krystol Magazine 14.2

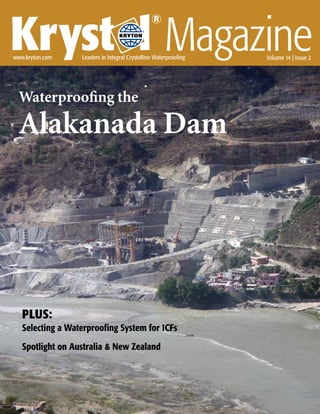

- 1. Kryst l Magazine ® ® www.kryton.com Leaders in Integral Crystalline Waterproofing Volume 14 | Issue 2 Waterproofing the Alakanada Dam PLUS: Selecting a Waterproofing System for ICFs Spotlight on Australia & New Zealand Krystol® Magazine 1

- 2. photo credit: dejahthoris WATERTIGHT CONCRETE. KIM® was selected as the waterproofing solution that could meet the technical complexities of the Aquarium at YVR within a tight schedule. Kryton’s unique self-sealing Krystol® technology waterproofs your concrete and protects your reputation. We assure you’ll meet and exceed spec because of our extensive testing, code approvals and conformance to ACI and PCA admixture guidelines for Permeability Reducing Admixtures under Hydrostatic water pressure (PRAH). Kryton’s concrete waterproofing system is used to waterproof the world’s iconic buildings, tunnels, dams and infrastructure developments of all sizes where quality is paramount. Contact us to see how we can help you. www.kryton.com ® +1-800-267-8280 At the Lab. In the Field. By Your Side.

- 3. Contents Volume 14 | Issue 2 4 Top Five Things to Know About Permeability Reducing Admixtures 6 Waterproofing a Dam in Rugged India – The Alakanada Dam 9 CEO Column 10 Selecting a Waterproofing System for ICFs 12 Kryton News 13 Ask a Kryton Expert 10 14 Kryton in Australia and New Zealand Learn about how to waterproof concrete while using Insulating Concrete Formwork (ICF). Krystol® Magazine is printed by 6 Kryton International Inc. 1645 East Kent Avenue Vancouver, BC V5P 2S8 Canada www.kryton.com For information about this publication or about Kryton International Inc., write to the above address, phone 604-324-8280 or 1-800-267-8280, or email info@kryton.com. Copyright © 2011 Kryton International Inc. All rights reserved. Editors/Contributors Alain Lok Kevin Davis Alex Emlyn Kevin Yuers Ali Biparva Sheila Dong Jeff Bowman Krystol Group PTY Ltd. Jillian Work Fraser Brown & Stratmore Ltd. Kari Yuers Design/Production Yvonne Lee Printed in Canada by Horseshoe Press Inc. Read how Kryton products are helping to extend the life of the concrete at the massive Alakanada Dam in India. Krystol® Magazine 3

- 4. Top Five Things to Know About Permeability Reducing Admixtures The American Concrete Institute (ACI) for Hydrostatic conditions (PRAH). at repelling rain water and reducing water is a long-standing, globally recognized The new categories do away with the ingress under damp conditions. institution that sets standards followed old terms of “damp-proofers” and However, with PRANs, the resistance to by the construction industry around the “waterproofers”, which were vague, water pressure is limited or temporary at world. Its extensive library of reports and poorly defined and lead to confusion best. As a result, PRANs are unsuitable body of educational programs has made regarding the capabilities and limitations for use in structures exposed to it an essential resource for all in of each admixture. hydrostatic pressure. the industry. PRAHs on the other hand, use a pore The recently re-published ACI 212.3R-10: blocking mechanism that makes them Report on Chemical Admixtures for capable of resisting water pressure. Concrete includes a new chapter, Chapter This allows PRAHs to be used in 15, specifically discussing permeability more demanding applications such Reducing Admixtures (PRAs). These as basements, tunnels and water admixtures reduce the rate at which water containment structures. PRAHs are enters into the concrete matrix. sufficiently stable to water under pressure that they can protect the structure for the Prior to the addition of Chapter 15, lifetime of the concrete. PRAs were mentioned only in passing as waterproofers or damp-proofers, and the 2. There are three different information was buried in a section of compositions of PRAs the report entitled “Miscellaneous”. Today, this specific category of admixtures has PRA materials fall into three broad found its rightful place. Below is a list of categories: 1) hydrophobic or water the top five things to know about PRAs. repellent chemicals, 2) finely divided solids or “densifiers” and 3) crystalline 1. There are two new categories chemicals. Water repellent chemicals of Permeability Reducing describe soaps, stearates and oils designed Admixtures to increase water repellency and reduce The Santa Lucia Canal in Mexico was adsorption. Finely divided solids are clay, waterproofed with a PRAH solution that Permeability Reducing Admixtures now could resist hydrostatic pressure. silica and polymers that take up space have a new system of classification. Today and densify the concrete. Crystalline all PRAs can be either categorized as With a PRAN, water absorption is chemicals hydrate with cement and Permeability Reducing Admixtures for reduced through the use of water water to reduce porosity and grow pore Non-hydrostatic conditions (PRAN) repellent chemicals or small, filler blocking deposits. This creates a network or Permeability Reducing Admixtures particles (densifiers). PRANs are effective of pore blocking crystals that becomes 4 www.kryton.com

- 5. 4. Some products claim to be PRAHs but are not Some products include a superplasticizer so they can be tested with a much lower water-cement ratio compared to a control concrete. This increases water resistance in the short term, but Crystalline chemicals fill the concrete’s pores blocking the flow of water. does not address the shortcomings of hydrophobic water repellents or finely integrally bound within the concrete. 3. Different testing methods are divided solids. These materials still The crystals will continue to form in necessary for each PRA category fuction as PRANs. Furthermore, not all the presence of water over the lifetime admixtures that claim to be crystalline of the concrete, and can even self-seal There are different means of testing a are true hydrophilic crystalline. Some leaking cracks. PRA – some are appropriate for testing chemical admixtures, such as those based PRANs, while others are only suitable on sodium silicate, merely “crystallize” Hydrophobic water repellent chemicals for testing a PRAH. Absorption tests, as they dry. This short term reaction are PRANs because the concrete pores such as BS 1881-122 (or ASTM C1585), is very limited compared to on-going are not blocked in any way. While immerse or partially immerse a sample of hydrophilic crystalline reactions, and finely divided solids provide some pore concrete in water and measure the weight does not provide the long-term water blocking and water resistance in damp gain over time. However, absorption tests resistance or self-sealing properties conditions, their resistance to water do not apply to water under pressure; required for an admixture to be a pressure is not stable enough to withstand therefore, they are inappropriate for PRAH. These admixtures are still long-term water pressure. Crystalline testing products that must withstand classified as PRAN. admixtures are PRAHs because they offer the highest and most stable water resistance, have self-sealing properties and continuously improve over time. Competitor A KIM Control (Untreated) Permeability test showing the depth of water penetration of three samples. hydrostatic conditions. A pressure driven 5. The long term success of a test, such as DIN 1048-5 or BS EN PRAH relies on three main factors 12390-8, is required to test whether an admixture is a PRAH because these are When choosing a PRAH, look for a the only tests that compare performance product that offers high levels of water under hydrostatic conditions. These resistance compared to a control (60 to tests apply pressurized water to one side 90 per cent improvement compared to a of a concrete sample over a period of control concrete) tested using a pressure time. Results are reported as a time to driven test and without the use of a full saturation, depth of water superplasticizer. It should also have the penetration or as a coefficient of following traits in order to act as a reliable permeability (a numerical expression of replacement for external waterproofing the concrete’s permeability). In a pressure membranes: the ability to improve over Absorption test showing how much water driven test, a PRAH should be able to time, the ability to self-seal hairline cracks was absorbed into the concrete block. demonstrate the ability to significantly and a long performance history. It is only Products that promote absorption testing reduce water penetration. by having all these features that you can are generally a PRAN. rely on your product to perform as a PRAH over the lifetime of your concrete. Krystol® Magazine 5

- 6. Waterproofing a Dam in Rugged India The Alakanada Dam The Alakanada River runs through the capital region of Delhi, the second and proximity to mountain run off. It foothills of the Himalaya Mountains largest metropolitan area in India, with a provided the best chance to develop and is a major water source for northern population of nearly 14 million people. hydro electricity and manage the level of India. In 2005 GMR Energy started the river. developing a 330 megawatt (MW) The project includes a 40 metre (m) hydroelectric dam and power plant on high dam, a three kilometre (km) long This site is nestled in a mountain valley. the riverbanks to help satisfy the headrace tunnel and an underground While the surrounding mountains are growing seasonal demand for power in penstock leading to an underground vast and breath-taking, it is a very remote northern India. power station with two 70 MW run of region that presents challenges to travel river turbines. The total head of water on and year-round work schedules. Getting Consistent electricity is one of the major the project is 480m. to the site requires a 340 km drive from issues facing India. Many homes and New Delhi on sometimes unreliable, businesses throughout India maintain The dam and power plant is located winding mountain roads, which can take gas generators to ensure a consistent just outside the town of Srinigar in 12 to 14 hours in travel time. The location supply of electricity. Most of the power Uttarakhand (formerly Uttaranchal) has snowfall for between four and six generated by the dam and power plant State in northern India. This site was months a year, so construction cannot will be channeled to serve the national chosen due to its location on the river take place during the winter. As a result, 6 www.kryton.com

- 7. Kryton has been working closely with the onsite ready-mix plant to optimize the mix design. waterproofing concrete with a of Srinigar. Modern day Srinigar was re- straightforward, dependable and established by the British between 1897 guaranteed system offers an indispensible and 1899. They used urban planning level of protection, particularly for dam methodology to create a new grid-iron walls with steel reinforcement. If water patterned town on the upper third terrace enters cracks in the concrete, it can southeast of the previous city site. The damage the reinforcing steel below the town was granted urban status in 1931 concrete surface. Steel expands when it and today is a major economic, cultural corrodes, which leads to more cracks and and educational centre in the region. water ingress. Over time, the concrete deteriorates and fails, which can result in Due to the extreme risk potential in devastating floods. building or waterproofing a dam, governments and engineers are turning The town of Srinigar is all too familiar increasingly to integral crystalline with the devastation of floods. On August waterproofing manufacturers for help. 26, 1894, over 10,000 million cubic feet Integral systems can add decades to of water from the breached Gohna Lake the life of a concrete structure. Unlike completely swept away the original town membrane systems that can deteriorate it is anticipated that it will take double DID YOU KNOW? the normal length of time to complete the project. The project is scheduled to achieve commercial operation in 2014. The Alakanada River forms one of the In addition, it is also an active seismic headstreams of the mighty River Ganges, zone at risk of earthquakes. On the holy river for followers of Hinduism. September 8, 1803, the area suffered Hindu followers believe the Alakanada a powerful earthquake that shook the River split off from the Ganges River when it whole region and devastated the town of descended from heaven. It originates from Lake Satopath, a triangular Srinigar. As a result, the engineering and lake 4,402 metres above sea level, high in the Nar and Narayan mountain ranges, construction teams have taken noticeable and flows 190 kilometres through the Alakanada Valley in Uttarakhand State. In steps to improve the soil stabilization on India, the river is also known as a destination for rafting and kayaking adventure the slopes surrounding the project area. trips. In fact, the Alakanada River is among the best in the world for river rafting due to its high grade rapids. Concrete is bound to crack if it is not properly placed or cured. Therefore, Krystol® Magazine 7

- 8. BY YOUR SIDE Approximately 1,000 tonnes of Kryton’s waterproofing system will be used to treat tens of thousands of square metres of concrete at the massive dam. over time, integral systems become part Membrane (KIM), to the dam face, canal of the concrete matrix, waterproofing and two tunnels. from the inside out. This gives these systems added reliability over other Going forward, the 1.8 km long canal waterproofing systems as they cannot leading to the pen stocks and two spillway be punctured or torn. In addition, tunnels that are each one kilometre long Kryton provided onsite and lab support for integral systems won’t be worn away will be waterproofed entirely using KIM. the project in India. by constant exposure to water, salts or Krystol T1 and T2 will be applied to the other contaminants and are not affected upstream section of the dam face, which by UV rays or concrete expansion and measures 128m by 340m. Kryton’s team has provided valuable contraction. Finally, integral systems onsite support to the crews working on are a green solution. They can extend In all, approximately 1,000 tonnes of the mammoth waterproofing project at the serviceable life of structures by Kryton’s waterproofing systems will be the Alaknanda Dam and continues to do decades and also allow the concrete to used to treat tens of thousands of square so today. be recycled after its useful life is over. For metres of concrete. hydroelectric dams, which are a green In addition to the initial site visit by form of energy, integral waterproofing Kryton’s Director of Sales Kevin Davis, systems make sense. the Delhi based sales and engineering staff has travelled to the dam several Kryton International Inc. became times since 2009. While there, they involved in the project in 2010 after provide onsite technical support for taking part in a site review meeting. concrete pours and application training. Although Kryton has been involved in constructing numerous hydroelectric Kryton also held a training program dams, this is the first time Kryton has for the engineering staff to ensure they contributed to the construction of a understood all of the steps that needed hydroelectric dam in India. to be taken in using the various products in Kryton’s waterproofing system. The Kryton is working with the onsite company worked with the onsite The two 1 km long spillways will be ready-mix plant to optimize the mix ready-mix plant to optimize the mix waterproofed with KIM. design. Achieving the optimum mix is design for the mass concrete and assisted proving to be challenging due to the Using Kryton’s waterproofing system on in reducing shrinkage cracking on vast annual temperature fluctuation at the dam face, canal and the tunnels concrete sections. the site. In addition, Kryton is helping offers a cost effective solution that will the onsite construction team to test surpass performance requirements and As the completion date for the dam is and apply Kryton’s surface-applied ensure the dam’s concrete structure a few years away, Kryton’s teams will waterproofing system, Krystol T1 and T2, remains durable, reliable and safe for continue to provide ongoing support and its internal system, Krystol Internal decades to come. and guidance to ensure the project is successfully completed. 8 www.kryton.com

- 9. CEO Column By: Kari Yuers, President & CEO, Kryton International Inc. I’ve been in the concrete industry for overseas distributors and customers. By changes we’ve seen in the information most of my life. My father created the late 1980s, the fax machine replaced technology world. Kryton International Inc. from the the Telex. ground up. My brother and I had our Over the years, if there is one steadfast chores as children – often sweeping With the arrival of the “World Wide Web” lesson I’ve learned about the concrete the factory floor and labeling pails of in 1989, you could communicate with industry, it is that relationships are Kryton products. In those days, we made anyone around the globe with an email important. Although technology has waterproofing treatments and at one address. Google has only existed for a given us a range of positives, I’ve most point had more than 150 products for little more than 10 years and current valued the new tools that have helped repairing, coating and building mainstays like Facebook and YouTube Kryton stay in touch with our concrete structures. didn’t exist even a half dozen years ago. distributors and customers. We’ve Each new technology, amazing in itself, integrated those new communication In 1991, I finished my studies, gained seemed to defy replacement by a superior tools to strengthen our relationships, and work experience and returned to invention, but that was not the case. to better serve the global market that my Kryton as Vice President of Technical father once envisioned. Services. Ten years later, I became Similarly, concrete has developed President and CEO. As I reflect on two from its simple origins as a mixture of Today, we no longer use the Telex. Instead, decades with the company, I am awed by rock, sand, cement and water into an we’re building online communities the rapid changes in technology and the increasingly complex and sophisticated through our blog, Concrete Thoughts overall marketplace. chemical product. The applications are (blog.kryton.com) and Krystol more versatile than ever – from soaring Connection e-newsletters you can sign up When Kryton first opened, my father skyscrapers to historical structures in for on our website. As new technologies envisioned a business that would serve a need of delicate restoration. come and go I would like nothing more global industry. Within two years, Kryton than the concrete industry to become secured its first international customer. Concrete has been used for thousands of early adopters of these advancements, In those pioneering days, I remember years, yet the innovations happening now putting us on the forefront of change. my mother sitting at the Telex machine are likely to create the same exponential Please join the conversations we’ve started sending and receiving information from and let’s stay connected. Krystol® Magazine 9

- 10. Worker treats concrete joints with the Krystol Waterstop System. Selecting a Waterproofing System for ICFs With growing pressure to build green, polystyrene, extruded polystyrene or move easily into formwork, filling even high performance structures – without closed cell polyurethane, these foam the most congested designs without the usual expensive eco-price tag – the forms interlock without the need for glue the vibration typically required in most global industry is readily embracing or mortar and retain structural strength ICF applications. Insulating Concrete Formwork (ICF). via plastic or galvanized steel ties. First developed in Germany in the 1950s, Concrete is inherently porous, so the technology is currently used in more Concrete is then pumped into the forms placement becomes critical to avoid than eight per cent of all low-rise housing in a circular pattern. This allows for better cold joining and honeycombing. in Canada and the U.S. According to concrete consolidation, mitigating air Unintentional joints can provide a a survey conducted by the Insulating pockets. Once set, the forms become high weak point where water ingress is more Concrete Form Association, 36 per cent strength and air tight. Since the forms likely to happen. Once the water enters, of builders say they have used ICFs in the stay in place, even after the concrete it can corrode reinforcement within last decade. Across the pond in the UK, has set, builders benefit from increased the concrete and lead to cracking and there is a growing number of approved durability, energy efficiency and sound structural deterioration. This is why basement walling systems that use ICF deadening. To further strengthen the many ICF structures need waterproofing. and the technology has been noted as a structure, reinforcing steel can also Modern Method of Construction by the be incorporated or steel fibres can be External Membrane Waterproofing Building Research Establishment, English added to the ready mixed concrete to an Partnerships and Communities England. engineer’s specification. A waterproofing membrane acts as an external barrier to prevent water from A large part of ICF popularity is its With the introduction of self- seeping into the ICF structure. Most often durability. The system is based on light- consolidating concretes, also known as they are polyurethane-based, spray or weight and hollow interlocking forms, self-compacting concretes, the efficacies brush applied or peel-and-stick. Solvent- which concrete is poured into. Composed of ICF’s have been further enhanced. based membranes, common in many of insulating foam such as expanded These flowable, non-segregating concretes other types of concrete construction 10 www.kryton.com

- 11. An ICF prior to application. Integral Crystalline Waterproofing structure. Water The ongoing challenges with that enters behind waterproofing membranes have led to the membrane a rise in the use of integral crystalline will also affect waterproofing for ICF systems. Part of its adhesion to the attraction is it can easily be added the concrete to concrete during the mixing process. surface, leading Once added, the chemical compounds to failure at the remain active for the life of the concrete. membrane seams The chemicals react with available water and weakening and cementitious components within the remaining dry the concrete to grow long, prism shaped concrete sections. crystals inside the capillary pores, cracks and joints, blocking water flow. If a new Installation with ICF crack forms later in the concrete and systems can also be a water penetrates, the chemicals react challenge. To properly adhere to stop water ingress. This ever-present membranes to ICF’s, the surface must chemical process ensures ongoing be clean, dry, smooth and even. Because waterproofing years into the future. membranes must be carefully wrapped around corners and protrusions, pipes, Because the waterproofing ability is conduit and other penetrations, the integrated within the concrete, crystalline installation crew needs to be skilled waterproofing systems can be used on any at cutting and lapping. Also, most concrete shape and cannot be scraped, membranes require a certain amount of punctured or torn. This makes the time space for correct installation. To meet consuming and often difficult installation this need, and to comply with Health and process of membranes obsolete. It allows Safety regulations, excavation size need other construction steps to proceed to be scaled up. This means higher costs without delay, saving time and money. for digging, handling and back filling as A luxury home in the United Kingdom being constructed out of ICFs. well as a possible restriction on the size of Finally, integral crystalline waterproofing basement you can build on a given plot. helps to create greener ICF structures. ICF systems are already well known for aren’t compatible with ICF systems their multiple environmental benefits – it because they destroy the foam. is estimated that every ICF home saves approximately eight and a half trees. External waterproofing systems tend ICFs also eliminate the soil erosion and to have much stronger tensile strength habitat destruction that is associated than rival waterproofing coatings and with timber building. Integral crystalline are always a consistent thickness. These waterproofing products extend the membranes can also effectively bridge serviceable life of concrete structures, cracks, joints and other defects. This can enable the future recycling of the be important when dealing with ICFs, concrete and also reduce jobsite waste which are frequently at risk of unseen – an ideal partner for the already eco- cold joints and honeycombing even friendly ICF system. though the surface of the concrete is rarely seen. Even though ICFs have been used in the construction industry for decades, their Despite these benefits, there are popularity and use is growing worldwide. challenges when it comes to effectively Selecting the right waterproofing product waterproofing ICF structures with for these systems is crucial. Regardless traditional membranes. Although of which method you choose, select a boasting good tensile strength, external high quality, dependable product – and membranes can be compromised by When waterproofing ICFs with external adhere to good concrete practices – to a single tear, making them vulnerable waterproofing systems the excavation needs ensure your ICF structure will remain to damage during backfilling and to be scaled up. Leading to higher costs as permanently dry. compaction. If the membrane is well as a possible restriction on the size of basement you can build on a given plot. punctured or torn, the damage is impossible to detect from within the Krystol® Magazine 11

- 12. Kryton News A Big Year for Kryton Understanding Kryton International Inc. is marking a major milestone in 2011. This year our CEO Kari Yuers celebrates 20 outstanding Kryton years with the company. Kari joined her family’s concrete waterproofing company in 1991 and has held various Customers leadership roles with the company in the last two decades. Under her leadership Kryton is always looking for ways as CEO, the company’s revenues have to improve themselves. Looking grown, market reach has expanded to improve the service to their key and it has been named the one of the audience groups, Kryton knew the first best companies to work for in British step towards achieving this goal was Columbia for three consecutive years. to listen. In order to learn more about Congratulations Kari! the individual needs of these groups, Kryton conducted an extensive market research program which was led by an independent consulting firm based in Chicago. Kryton wanted to know A Coast to Coast Kryton what their customer’s concerns were, what challenges they faced, and what factors were crucial to their success. Kryton International Inc. is a proud the prairies. Arrow Construction Products The researchers were able to obtain Canadian company that has had success is a great fit for Kryton in the Atlantic current and unbiased information from in western markets for years. When the Provinces. With five branches across these groups. recession hit, and construction slowed Eastern Canada, they are well known for down, Kryton’s strategic response was to their great customer service and are very Although it was a time and resource expand. The idea was to plan ahead by active in the market. consuming program, the findings were developing a foundation in Central and well worth the investment. Kryton Eastern Canada so that when the industry has undertaken to provide the tools began to recover our presence would be and resources along with relevant strong; catching more fish by casting a information to each audience segment. wider net. Delivering on customer needs is core to Kryton’s business model. So whether For Kryton, finding the right distributor you are a contractor, owner, architect or is extremely important as they drive the engineer, Kryton has the right solution product forward, impact the quality of the to help you. technical support and must collaborate with all of the other groups in the project. All these factors and more are considered when Kryton selects their distribution partners. After a thorough search, Kryton has found four new distributors who meet Canada continues to build innovative their criteria. buildings and infrastructure from coast to coast. Kryton has now expanded our In Ontario, Form and Build Supply distribution relationships to be able to represents Kryton with their five offer solutions to every major city locations throughout Southern Ontario across the nation. Kryton is now and their sub distribution partners protecting concrete structures from the in other areas such as with Alpine Pacific to Atlantic Oceans as well as from Construction Supplies in Ottawa. In many bodies of water and high water Manitoba and Saskatchewan, Nu West tables in between. If you are building Construction Products stepped forward concrete structures and are trying to keep as the company that would take on water in, out or both, Kryton is your Krystol products and push them across Canadian solution. 12 www.kryton.com

- 13. Ask a Kryton Expert! Preventing Concrete Corrosion Deteriorating concrete structures are a major problem around the world. Largely attributed to the corrosion of steel reinforcement, concrete structures built to last 50 to 100 years routinely need substantial repairs and rehabilitation during their service life. Why are traditional preventative measures for corrosion not sufficient? More importantly, what is the solution? Kryton expert, Alireza Biparva, explains. How Corrosion Happens Concrete normally provides reinforcing Proper curing helps to minimize shrinkage and cracking. steel with excellent corrosion protection. Due to the high alkalinity of the concrete, Under the best conditions, the It is important to use a concrete mix the steel reinforcing bars are passivated penetration of moisture, chlorides and with low permeability and to use an by an iron oxide film that protects the carbon dioxide is slow, the passive layer appropriate amount of concrete cover for steel. However, the passive layer can break is protected and corrosion is minimal. the application. Additionally, the concrete down over time due to atmospheric Concrete’s ability to resist corrosion should be placed, consolidated and cured carbon dioxide. Through a process called depends largely on the permeability of following ACI guidelines to minimize carbonation, the concrete’s pH is lowered the concrete and the thickness of concrete shrinkage and cracking. With good until the passive layer becomes unstable. cover over the reinforcement. However, if materials and workmanship, concrete The passive layer can also be rapidly cracks are present, aggressive agents can can resist the development of corrosive broken down by aggressive chemicals quickly reach the depth of the steel and conditions, which increases the durability such as chloride, which are present in initiate corrosion. of structures and reduces lifetime coastal environments and used in deicing maintenance costs. chemicals. Once the passive layer is Traditional measures to mitigate compromised, steel reinforcement will corrosion have proven to be less effective corrode if there is moisture and oxygen than desired. Excessively thick concrete present at the surface of the steel. cover over the reinforcing steel is vulnerable to cracking and corrosion inhibitors such as calcium nitrite provide only temporary protection. Epoxy coated reinforcement was once thought to be a solution but has proven unreliable in field applications. The problem is these systems do nothing to prevent the conditions that cause corrosion from developing in the first place. So what is the solution? Preventing Corrosion In all cases, the penetration of water into concrete is a critical factor in the corrosion of steel reinforcement. Water acts as a carrier for chloride ions and is also required for corrosion to occur. Therefore, the first line of defense against corrosion is to prevent the Alireza Biparva, Cementious Materials Extreme corrosion can result in major leaks. penetration of water. Specialist at Kryton International Inc. Krystol® Magazine 13

- 14. Kryton in Australia and New Zealand The global construction industry has had its fair share of the next year, particularly in the earthquake-affected region economic challenges over the last three years. Australia and New surrounding Canterbury. In addition, 75 per cent of architects Zealand’s industries are no exception. But an increasing demand in New Zealand surveyed by international property and for resources-based construction as well as progress on major construction consultants Davis Langdon are expecting new infrastructure projects has started to turn the tide. business to increase – a sign of more construction activity on the horizon. According to a survey by Australian Industry Group and Australian Constructors Association, the value of construction Kryton has been operating in Australia for more than 30 years projects in the country will rise by almost eight per cent in 2011 and New Zealand’s construction industry for almost a decade. and 2012. In New Zealand, the restoration and refurbishment With industry steadily growing, Kryton will continue to be a key sectors are predicted to contribute the most to growth over player in the region for years to come. Te Wharewaka O Poneke (Canoe House), Taupo, New Zealand Sitting on reclaimed land along the waterfront in central Wellington, the Te Wharewaka O Poneke (Canoe House) is a new development that will serve as an entertainment centre for the Rugby World Cup in September and October 2011. Showcasing the rich history of Maori art and culture, the venue will include exhibition and function areas, a café and offices. It will also host powhiri (a Maori ritual ceremony), carvings, cultural performances and interactive historic displays. More than 1,100 kg of Kryton’s Krystol Internal Membrane (KIM) was used to waterproof 1,600 cubic metres of concrete in the slab and surrounding concrete landscape. With its location adjacent to the ocean, KIM was the optimal choice for this project where water exposure or ingress is a concern. Westfield Shopping Centre, Sydney, Australia Once completed, this high-end boutique shopping centre will house 130 fashion and food specialty stores including some the biggest style icons such as Gucci, Hugo Boss, Mulberry and DKNY, as well as Australian retailers CUE, Wanted Shoes, Zimmerman and Carla Zampatti. On the recommendation of contractors, Kryton’s Krystol Waterproofing System was selected to waterproof the basement walls, lift pits, water tanks and cool-rooms. To date 350 cubic metres of KIM have been used for the project, which began on November 19, 2009 and continues today. Australian Red Cross Blood Services, Melbourne, Australia The Australian Red Cross Blood Services purchased a 16,500 square metre former warehouse for their Melbourne operations but stringent modifications were needed before the building would be able to house the blood bank. The consulting engineers chose Kryton’s waterproofing system because it was seen as the best solution for the job. To date, the project team has used more than 200 cubic metres of KIM to waterproof the substation, plant-room, switch room and trenches. The project is running on schedule and due to complete later this year. 14 www.kryton.com

- 15. IKEA Store, Princes Highway Tempe, Sydney, Australia The 37,000 square metre store (equivalent to 20 football fields) with parking for 1,775 cars, sits on a 2.3 hectare site located southwest of Sydney’s central business district. Like all IKEA stores, the building is a two-level rectangular shaped building that includes a showroom, restaurant, children’s play area, warehouse, Swedish food market, office space, public amenities and loading dock. Upon completion, the building will be the Southern Hemisphere’s biggest IKEA Store and is expected to attract between two and three million visitors annually. Making the store unique, the building is being constructed on an old garbage dump site. As a result, methane gases exist underneath a portion of the new structure. A 700 metre methane gas wall is being constructed to allow ventilation of the gases. Based on a previous experience, the team of contractors chose Kryton products for waterproofing the below-grade areas, lift pits, travelators pits, basement sections and water tank. Just over 100 cubic metres of KIM-treated concrete were used to waterproof the below-grade areas of the new store. Sea World Penguin Exhibit, Gold Coast, Australia Sea World’s new Penguin Encounter exhibit is home to a large waddle of King Penguins, the world’s second largest penguin species. The designers wanted to create an environment that looked as natural as possible, while retaining the required engineering attributes. The ambient summer temperature in sub-tropical Queensland is close to 40 degrees Celsius, but the penguins’ water is chilled to two degrees Celsius.The constant movement at the waterline creates both significant physical wear on the concrete structure as well as temperature variation. Kryton’s KIM was chosen as a solution for waterproofing the artificial rock in the exhibit. KIM’s self-sealing ability means that despite temperate changes, the wearing effects of the waterline and penguins clawing at the rock, the waterproofing will remain durable and reliable for the lifetime of the structure. Australia & New Zealand Distributors Kryton has exclusive distributors throughout Australia & New Check out www.kryton.com to see other areas where Kryton Zealand. Contact any of them to find out more about how distributors are changing concrete construction for the better, Kryton’s waterproofing products can save you time and money. throughout the Americas, Europe, Middle East, India and Or contact Alain Lok, Kryton’s Asia-Pacific Regional Manager at Asia-Pacific. alain@kryton.com or by phone at +1-604-324-8280. New Zealand New Zealand Australia AUTHORIZED (Auckland) (Wellington and South Island) (NSW, VIC, ACT, QLD, WA) DISTRIBUTOR Fraser Brown & Stratmore Ltd. Fraser Brown & Stratmore Ltd. Krystol Group Pty Ltd. Contact: Mr. Denis Marra Contact: Mr. Hamish Stratmore and Contact: Mr. Aaran Duncan Tel: (649) 535-3139 Mr. Craig Meiklejohn Tel: (612) 9545-3111 Website: www.fbsltd.co.nz Tel: (644) 567-8436 Website: www.krystol.com.au Email: denis@fbsltd.co.nz Website: www.fbsltd.co.nz Email: aaran@krystol.com.au Email: hamish@fbsltd.co.nz Krystol® Magazine 15

- 16. Concrete Waterproofing that Works! KIM® resists hydrostatic pressure up to 140m. Using KIM® in your concrete can save you time and money and replace the need to use costly and time consuming surface applied membranes that can often prove to be unreliable. Since 1973 Kryton has helped architects, engineers and builders create dry, waterproof concrete using Krystol Technology. Our waterproofing admixture, KIM®, is faster, more reliable and costs 25% less than using traditional waterproofing systems. KIM® is backed by the industry’s longest warranty. For more information on the longest standing Custom bags for added quality control crystalline waterproofing admixture jobs in the world, visit us online at www.kryton.com or call us at 1-800-267-8280 or +1-604-324-8280. Certified to CERTIFICATE No 05/4217 NSF/ANSI 61 ® At the Lab. In the Field. By Your Side.