Internal constrain

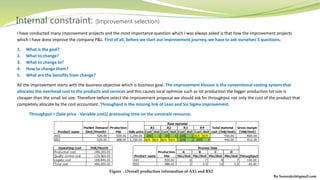

- 1. Figure : Overall production information of AX1 and BX2 I have conducted many improvement projects and the most importance question which I was always asked is that how the improvement projects which I have done improve the company P&L. First of all, before we start our improvement journey, we have to ask ourselves 5 questions. 1. What is the goal? 2. What to change? 3. What to change to? 4. How to change them? 5. What are the benefits from change? All the improvement starts with the business objective which is business goal. The improvement illusion is the conventional costing system that allocates the overhead cost to the products and services and this causes local optimize such as lot production the bigger production lot size is cheaper than the small lot size. Therefore before select the improvement proposal we should ask for throughput not only the cost of the product that completely allocate by the cost accountant. Throughput is the missing link of Lean and Six Sigma improvement. Throughput = (Sale price - Variable cost)/ processing time on the constrain resource. By Sornrakrit@gmail.com Internal constraint: (Improvement selection)

- 2. Process A C/T : 6 Minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 minute Process B C/T : 7 minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute Process C C/T : 8 Minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute Process D C/T : 7 minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute I I I I I 120 pcs 120 pcs 120 pcs 6 min 7 min 8 min 7 min 360 min 840 min 960 min 260 pcs 2880 min 28.0 min 720 min 1 X Weekly shipment 1 X Monthly shipment 500 pcs 90/60/30 day forecasts Weekly order 3/1 Month forecasts Monthly order Production control Daily order 130 PCS/Week Tray = 52 PCS Figure : Value stream mapping for product AX1 Throughput concept By Sornrakrit@gmail.com

- 3. Process A C/T : 3 Minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 minute Process B C/T : 3.5 minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute Process C C/T : 14 Minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute Process D C/T : 3.5 minute C/O : 60 Minute Takt : 18.4 Min Shift : 1 shift Available : 9,600 Minute I I I I I 120 pcs 120 pcs 120 pcs 3 min 3.5 min 14 min 3.5 min 360 min 1680 min 420 min 260 pcs 2280 min 24.0 min 420 min 1 X Weekly shipment 1 X Monthly shipment 500 pcs 90/60/30 day forecasts Weekly order 3/1 Month forecasts Monthly order Production control Daily order 130 PCS/Week Tray = 52 PCS Figure : Value stream mapping for product BX2 (Before improvement) Throughput concept By Sornrakrit@gmail.com

- 4. Hereafter is the example of how conventional costing give us the illusion. Throughput is the indicator to measure process rate at the constrain resource of the organization. In order to simplify, I will use the value stream mapping of the product as example and we will consider only the production process time improvement only. We will not consider the inventory reduction and the lead time reduction which could impact to the customer satisfaction even these are also importance KPIs which most of the conventional company use them. In this example, Assume that there are 2 improvement options which propose from the different engineer: Option A: Mr. A proposes to reduce production time of product BX2 in process B and D from 3.5 minute to 2.5 minute and this require investment 10,000 THB. For this improvement proposal, the production lead time reduces 2 minute which equal -7%. Option B: Mr. B proposes to reduce production time of product BX2 in process C from 14 minute to be 13 minute, but it need to increase production time in process A from 3 minute to 6 minute. This improvement requires investment 15,000 THB. For this improvement proposal, the production lead-time increase 3 minute which equal +8%. As you are the management which option you will select and why. In Lean and Six sigma Concept we all will select Option A instead of Option B because option A we reduce the process time in Process B 1 minute from 3.5 minute to 2.5 minute (28.57%) and Process D 1 minute from 3.5 minute to 2.5 minute (28.57%) and the total process will reduce 2 minute from 24 minute to 22 minute (8.33%). Moreover, the investment cost for option A is only 10,000 THB which less than Option B around 33 %. In option B, we reduce the process time at process C 1 minute from 14 minute to 13 minute (7.14%), but in process A the process time will increase 3 minute from 3 minute to 6 minute (100%) and the total process time increase 2 minute from 24 minute to 26 minute (8.33%). However, we should consider both option A and B base on the financial result as well. Figure : Company profitability before improvement Throughput concept By Sornrakrit@gmail.com

- 5. Figure : Company profitability after improvement (Option B) Figure : Company profitability after improvement (Option A) The profitability after improvement option B is higher than option A and higher than before improvement due to the company can produce the product BX2 30 unit more than before improvement and this product still can be sold because production mix is lower than the market demand. In short, the real improvement of the system is the improvement that increase the capability of the system. Throughput concept By Sornrakrit@gmail.com

- 6. Improvement projects Cost saving Positive impact to P&L project Negative impact to P&L project Capital for reinvestment in the improvement projects Company profit Investors attractiveness Stock price New investment capital New investors I would like to explain about the green loop which is the reinforce loop first. If we selected the improvement projects that have positive impact to P&L, we will gain more cost saving and we can use the cost saving for reinvestment in the remaining improvement projects that have positive impact to P&L also. More cost saving will increase company profit. Once the company profit higher than the industrial average, it will increase the investment attractiveness. When the investment attractive increase, it will lead to the increasing in stock price. Once stock price increase, the new investors will willing to invest in the company stock. Then the company will gain the new investment capital from the new investors which the company will invest in the improvement projects. When the company profit increase, The company can pay more dividend to the stockholder, employee welfare, salary adjustment and bonus. Good salary, welfare and bonus will attract the talent people to join the company. The more talent people join the company, the more improvement project will be proposed and it will start the process again as cycle. The red path is the contrary with the green path. Employee welfare and bonus Dividend Amount Talent people join the company Reinforce loop By Sornrakrit@gmail.com