weaving.pptx

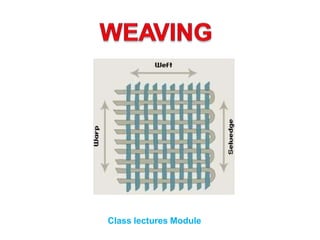

- 2. TEXTILE A Textile was originally a woven fabric but now the term textile and its plural textiles are also applied to fibers, filaments, yarn and most product for which these are a principle raw material, the product includes threads, cords, ropes, braids, woven, knitted, non-woven fabrics, nets, household textile, geo-textile, medical textiles etc. WEAVING Weaving is the action of producing fabric by the interlacing of warp and weft thread. The warp threads are placed along the length of the fabric and the weft threads are placed along the width of the fabric.

- 3. FLOW CHART OF WEAVING Yarn (In the form of spinner’s package) Warp Preparation Winding (cone, cheese) Weft Preparation Winding (Cop, Pirn, Cone, Cheese) Warping (Pre beam/ Warper’s beam/ back beam) Weaving (Fabric) Sizing (weavers beam) Drafting, Drawing, Pinning Denting, Looming

- 4. Geo-Textile: Embankment Medical Textile: Non-alginate fabric Three types of yarn package are mention bellow Cone Flange bobbin Cheese

- 5. TYPES OF FABRICS 1. Woven fabric (Shirt) 2. Knitted fabric (T-shirt) 3. Non-woven fabric (Tea pack) 4. Special fabric (Fire proof fabric, water proof fabric) OBJECTS OF YARN PREPARATION 1. To remove yarn faults ( there are 23 types of yarn faults) 2. To transfer the yarn from spinner package to a convent form of package which will facilitate weaving. 3. To have desired length on a package. 4. To clean the yarn for better appearance and performance. 5. To make good quality fabric. 6. To reduce labor cost.

- 6. Intentional FAULTS TO BE REMOVED DURING YARN-PREPARATION 1. Thick place 2. Thin place 3. Slubs 4. Lose fibers 5. Count variation Unintentional 6. Foreign particles (seed, slub, leaf, dust, bollworm, honeydew) 7. Neps

- 7. QUALITY OF GOOD WARP 1. The yarn must be uniform, clean and free from knots as much as possible. 2. The yarn must be sufficient strong with withstand the stress and friction without end breakage. 3. Knots should be a standard size and type. So that they can pass the heald eye, dropper, read easily. 4. The warp must be uniformly sized and size coating should be thick enough to protect the yarn various function. 5. The ends of warp must be parallel and each must be wound onto a weavers beam at an even and equal tension. 6. All warp yarn should of same size in length.

- 8. PACKAGE TYPES OF PACKAGE 1. Cone 2. Cheese 3. Spool 4. Flange bobbin 5. Cop (use for jute weft) 6. Pirn (use for cotton weft) 7. Spinner’s bobbin

- 9. TYPES OF PACKAGE WINDING There are three types of package winding available. 1. Parallel wound package 2. Near parallel wound package 3. Cross wound package Parallel Wound Package Features • • • • • • • Much yarn can be wound at a time. No need of traversing motion. Side withdrawal is possible. The density of yarn is more. No change of twist/inch. For yarn unwinding separate mechanism is needed. Two side of the package needed flange.

- 10. Near Parallel Wound Package Features 1. No need flanged here. 2. Both side and overend withdrawal is possible. 3. Twist/inch can be changed. 4. Traversing motion is needed. Cross-Wound Package Features 1. Here no flanged is required. 2. Traversing mechanism is must. 3. Twist/inch changes. 4. Only overend withdrawal is possible. 5. Yarn ballooning occurs during unwinding. 6. This package is very stable.

- 11. PACKAGE DRIVING TYPES OF PACKAGE DRIVING There are three types of package driving system. 1. surface contact driving (indirect system) 2. direct driving at constant angular speed 3. Direct Driving At Variable Angular Speed 1. SURFACE CONTACT DRIVING (INDIRECT SYSTEM) In this system, the yarn package is placed with a surface contact of a drum. The drum is driven by a motor and same gear. When it rotates the package also rotate is reverse direction.

- 12. 2. DIRECT DRIVING AT CONSTANT ANGULAR SPEED In this system the package is placed on a spindle and spindle gets motion by a motor and some gears. So, that package gets a constant angular speed. Here yarn take up rate is directly proportional to the package dia.

- 13. 3. DIRECT DRIVING AT VARIABLE ANGULAR SPEED In the system yarn package is directly driven at a variable angular speed to give a constant yarn speed. Here the package speed is inversely proportional to the package radius, I.e. Package speed 1 Package radius

- 14. BALLOONING The appearance of the curved path of running yarn during unwinding or over end withdrawn from packages under appropriate winding condition through a guide, placed above and in line with the axis of the package at an adequate distance from it, the yarn assumes the appearance of a balloon shape. This circumstance of assuming balloon shape of yarn is called ballooning.

- 15. FACTORS EFFECTING THE SHAPE AND SIZE OF BALLOON 1. Package size Ballooning 2. Yarn guide distance Ballooning 3. Lift the package Ballooning 4. Count of yarn Ballooning 5. Air resistance Ballooning 6. Unwinding rate. Ballooning

- 16. YARN WITHDRAWAL OR UNWINDING The unwinding process of yarn from a package is called yarn withdrawal. There are two types of yarn withdrawal system: 1. Side Withdrawal 2. Overend Withdrawal 1) Side Withdrawal The features of side withdrawl of yarn are given bellow; a. Package will rotate in side withdrawal. b. Yarn twist will be unchanged. c. No formation of balloon occurs. d. It is applied to flanged bobbin. e. The rate and speed of unwinding is slow.

- 17. 2. Overend Withdrawal The features of overend withdrawl are given bellow; a. Package remains stationary during unwinding. b. Formation of balloon occurs. c. Twist/inch of yarn changed. d. Generally cop, pirn, cone, chess are packages used for overend withdrawl. e. The rate of unwinding is high.

- 18. YARN GUIDE In winding and unwinding some small component control yarn path which is very necessary, yarn guide is used to perform this job. TYPES OF YARN GUIDE There are two types of yarn guide 1. Yarn Guide For The Yarn Whose Ends Are Required For Threading; For this type of yarn guide extra time is needed for threading. So speed of operation is decreased. The yarn which passes this guide faces more friction. Like Ceramic, Tumpet, Bust 2.Yarn Guide For The Yarn Whose Ends Are Not Required For Threading; Here threading is very easy. So the speed of the operating is high. Yarn passes through this guide faces less friction. Figure: Yarn Guide

- 19. TENSION DEVICE During winding, we have to impart proper tension to yarn, so that we can get a stable and undamaged package. So we pass the yarn through a device called tension device. Types of Tension Device There are four types of tension device as follow; a) Capstan Tensioner. b) Additive Tensioner. c) Combined Tensioner. d) Automatic Tensioner.

- 20. A.CAPSTAN TENSIONER It is the simplest type of yarn tensioner. It works only by deflecting the yarn around fixed posts. This includes a capstan effect on yarn. It works by the following formula: Output Tension = Input Tension × eμ θ or, T2 = T1 e μ θ Where, T2 = Output tension. T1 = Input tension. e = Constant μ =Co-efficient of friction. θ= θ 1+θ-2+ θ 3 = Angle of lap.

- 21. B. ADDITIVE TENSIONER This is also a simple technique of applying tension of yarn. In this device a dead weight or spring is used in the middle of the two surfaces in contact and the force is applied to give suitable tension to the yarn. Hence the output tension is expressed by, T2 = T1 + 2μF Where, T1 = Input tension. T2 = Output tension. µ = Co-efficient of friction. F = Applied force.

- 22. C. COMBINED TENSIONER It is the combined form of additive and capstan tensioner. The device permits the tension level to be raised to any desired level, but doesn’t permit a reduction of tension. Here output tension is expressed of follow: T2 = T1 + 2μ F = T1 eμ θ Where, T1 = Input tension. T2 = Output tension. µ = Co-efficient of friction. F = Applied force. θ= Angle of lap.

- 23. D. AUTOMATIC TENSIONER It is a simple tensioner in which yarn tension is controlled automatically. It has a lever with spring loaded disc in one side and applied load in another side. The device is designed in such a way that if applied tension is too high. The pressure on disc is reduced to bring the tension back to its proper level.

- 24. EFFECT OF TENSIONING DEVICE There are some effects of tension to yarn or package: They are a) If tension is too high. b) If tension is too low. c) If tension varies. • • • • • a) If Tension is Too High Hard package. Breakage rate increase. Yarn elongation. Shade variation. Weak the thin place. • • • b) If Tension Is Too Low Loose package Unstable package Slough off • • • c) If Tension Varies Problem during unwinding Package unstable Irregularity among yarn Auxiliary Function in Winding • Creeling. • Piecing. • Doffing.

- 25. CHOICE OF TENSIONING DEVICE • It must be reliable. • It must be easily threaded. • It must neither introduce nor mainly tension variation. • It must not change the twist of yarn. • It must not be affected by wear. • It must be easily adjustable. • It must not be affected by the presence of oil and dirt. • It must not encourage the collection of dirt and lint. • It must be easy cleaning. • The operating surface must be smooth. • It must be cheap. •It must not cause any type of damage to yarn i.e. shade variation, elongation yarn breakage.

- 26. WINDING PRECISION WINDING FEATURES • Packages are wound with reciprocting traverse. • Package contains more yarn. • Low stability of package. • Hard and more compact package. • Low unwinding rate. • The wound coil are arranged parallely or near parallely. FEATURES OF NON-PRECESSION WINDING • Coils are cross wound. • Package is of low density. • Less amount of yarn is stored in package. • High stability of package can be obtained. • Flange is not necessary. • Unwinding rate is very high.

- 27. MATH-1 Given Production= 560yd/min/drum, 24 Ne, yarn= 500lb, time=? Solution 24 Ne means, 1 lb. of yarn contain = 24X840 yds. yarn 500 lbs. of yarn contains = (24X840X500) yds. yarn 560 yds. of yarn to wind in 1 drum needs =1 min 1 yd. “ “ “ (24X840X500) yd “ “ 15 drum “ 15 drum =1/ (560X15) min. = (24X840X500) / (560X15) min. =1200 min. =20 hr.(ans.)

- 28. Math-2 Given, Production=600yd/min/drum 25 Ne, Yarn=900 lbs, time=28 hr., Find number of drum. Solution 25 Ne of yarns means, 1 lb of yarn contains 500 lb of yarn contains = 25X840 yd yarns. = (25X840X900) yd yarns. 600 yds. of yarn to wind in 1 1 yd ’’ ’’ ’’ min in = 1 drum (60X28) min in = 1 / (600X60X28) drum. (25X840X900) yds. ’’ (60X28) min = (25X840X900) / (600X28X600) drum = 18.75 drum = 19 drum (ans.)

- 29. WARPING OBJECTS OF WARPING • To prepare a beam to make a fabric. • To increase the weave ability of fabric. To make a convenient yarn sheet for sizing. To wound up required length of yarn onto a warp beam. To facilate the weaving of complex color pattern. To make reusable small packages • • • • Winding is a part of total number of ends of a warp in full width on to a back beam from cone or cheese is known as warping.

- 30. REQUIREMENT OF WARPING During warping the following requirement should be fulfilled. 1. The tension of all wound ends must be uniform and possibly constant throughout the withdrawal process. 2. Warping should not impair the physical and mechanical properties of yarn. 3. The surface of warping package must be cylindrical. 4. A pre-determined length of yarn should be wound on beam from every package. 5. The production rate of warping is as high as possible. 6. If possible, yarn faults should be removed

- 31. TYPES OF WARPING Mainly there are two types of warping, a) Direct/ high speed warping b) Sectional warping. Some Other Special Types of Warping Are Available a) Ball warping b) Chain warping c) Cross warping A) DIRECT/HIGH SPEED WARPING High speed warping is a process of preparing warp beam directly from yarn package. Here all the yarns are wound on a simple flange beam at a time. This process is suitable for single color pattern. B) SECTIONAL WARPING Sectional warping is a process of preparing warp beam over two stages. In first stage yarns are wound in narrow tapes on a large drum. Then in the second stage the rewinding of the warp onto a beam is slow but suitable for complex color pattern.

- 32. FEATURES OF SECTIONAL WARPING • Sectional warping is suitable for producing color fabrics with different pattern. • Production in sectional warping. So it is costly process. • In sectional warping tension cannot be kept uniform. • Tapered drum is used as drum here. • Hand weaving is necessary to produce for simple fabric for bulk production FEATURES OF HIGH SPEED WARPING •High speed warping is suitable for producing fabric with same count & same color yarn. • Higher amount of yarn is required here. • The speed & production of a high speed warping is very high. • Here simple flanged.

- 33. Control System in Warping • Tension control • Balloon control • Stop motion • Yarn cleaner • Length control • Surface speed control • Proper yarn density • Static electricity • Traverse control • Fly control Faults in Warping • Off center warp • Rigid or uneven warp • Cross end • Sinker formation • Hard/soft beam • End missing • Haphazard knotting • Length deviation

- 34. Relation between Taper Angle and Amount of Yarn on a Beam Let, s = traverse length. L = axial d = empty beam dia. D = full beam dia. dm = = mean dia. X = tape distance α = taper angle v = volume of yarn stored on beam. Let, s >x so as to maintain stability. V = - = ( From figure, it is clear that - ) = πL ( ) ( ) So, v = π L dm (x tanα) V > π L dm S tan α V < π L dm S tan α if, x > s if, x < s So, V S tan α if α = 90° then V = α So unlimited amount of yarns can be wound if flange stays perpendicular to beam barrel. Practically this is impossible. But this type of package permit’s to wind high amount of yarn. dm = = x tan α

- 35. SIZING The method of applying a gelatinous film forming substance of starch on warp yarn before weaving is known as sizing. Object of Sizing •To protect the yarn from abrasion with heald eye, back rest, reed etc. during weaving. • To improve breaking strength of cellulosic yarn. • To increase yarn smoothness. • To reduce yarn hairness. • To increase yarn elasticity and stiffness. • To decrease yarn extensibility. • To hinder generation of static electricity for synthetic and blended yarn. • To increase yarn weight.

- 36. Sizing Ingredients and Their Functions Some important size ingradients and their functions are mentioned below- 1. Adhesive 2. Lubricants or softeners 3. Antiseptic or antimildew agent 4. Deliquescent or Hygroscopic agent 5. Weighting agent 6. Anti-foaming agent 7. Tinting agent 8. Wetting agent TECHNOLOGICAL CHANGES OCCURE DUE TO SIZING The following technological changes of a yarn/fabric occurs due to sizing – 1. INCREASE IN BREAKING STRENGTH 2. INCREASE ABRASION RESISTANCE 3. INCREASE IN STIFFNESS 4. INCREASE IN ELASTICITY 5. INCREASE IN FRICTIONAL RISISTANCE 6. INCREASE IN YARN DIAMETER 7. DECREASE IN YARN HAIRINESS 8. DECREASE IN STATIC ELECTRICITY FORMATION

- 37. Size Take Up Take Up Percentage Depends On The Following Factors • Twist. • Yarn count. • Viscosity of size material. • Speed of yarn passing through m/c. • Pressure of squeezing roller. • Amorphousness of fiber in yarn. • Flexibility of yarn. • Nature of adhesive. • Time and temperature. SIZE TAKE-UP PERCENTAGE Size take up % = Wt. of size material o yarn × 100 Wt. of unsized yarn

- 38. Twist S.T Yarn count S.T Viscosity of size material S.T speed of yarn passing through m/c S.T Pressure of squeezing roller. S.T Amorphousness of fiber in yarn. S.T Flexibility of yarn S.T Nature of adhesive. S.T Time and Temperature. S.T Size Take up Percentage Depends on the Following Factors

- 39. SIZE CALCULATION MATH-1: A beam of wt. 290 lbs. contains 3500 sized warp of 1300 yds length. It the unsized yarn count is 28 Ne and empty beam wt. 70 lbs., then calculate - 1. Wt. of size on yarn. 2. Count of sized yarn. 3. Size take-up percentage.

- 40. LOOM The loom is the contact point of the whole process of cloth production, ginning, opening, carding, spinning, winding, warping, sizing and beaming are done before weaving. A loom cannot be said a machine but it is a device which is used to produce woven fabric. Looms are generally driven either by line shaft or by individual motors fitted with it. Weaving Mechanism / Basic Principle of Weaving Weaving is the process of interlacement between the warp and weft in fabric according to a design of fabric. Basic principle or weaving mechanism is: •The yarn from the weavers beam passes round the back rest and comes forward through the drop wire of the warp stop motion to the heald eye of heald shaft which is responsible for the purpose of shade formation. •It then passes through the dent of reed which holds the thread at uniform spacing and it is also performed the beating up the weft thread that has been left in the triangle warp sheet form by the two warp sheet and reed. •In this way, weft yarn is meshes with last pick of fabric or cloth. Temple holds the cloth firm at the feed position and assist in the formation of a uniform fabric width. Then fabric passes over the front rest, take up roller, pressure roller and finally wind on to the cloth roller.

- 42. DRIVING MOTION ➢It is seen that the figure that, two tappet mounted with the one bottom shaft and it passed the treadle lever by treadle bowl to down direction. ➢There is a fulcrum at the end of treadle lever and another end of lever is joined with heald shaft by yarn. ➢Top roller acts as intermediate of two rope of heald shaft from which rope passes over the top roller. ➢When shedding cam or tappet pressed on the treadle lever by treadle bowl, then one heald shaft is down while another is up and shedding is formed. Such way, 2nd shedding tappet reverses full motion i.e. upper heald shaft is down and down heald shaft is up. ➢The mechanism of a power loom receives their motion from shaft that traverses from side to side in the loom and is driver from another. Their relative speeds are of importance since they give the mechanism that they drive. ➢The crank shaft being driven by the motor moves one revolution per picks. The motion of the teeth of the gear wheels connecting this shaft to the bottom shaft is always 2:1, so that the bottom shaft will move one revolution in ever two picks.

- 43. CLASSIFICATION Loom Hand Loom Power Loom Ordinary Power Loom Automatic Power Loom Modern or Shuttle less Loom

- 44. Hand Loom 1. Primitive or Vertical loom. 2. Pit loom (a) Throw shuttle loom. (b) Fly shuttle loom. 3. Frame loom (a) Throw shuttle loom. (b) Fly shuttle loom. 4. Chitttaranjan loom. 5. Hattersley loom Modern or Shuttle less Loom 1. Projectile Loom. 2. Rapier Loom. 3. Air jet Loom. 4. Multiphase. Ordinary Motor 1. Common Motor. 2. Individual motor.

- 45. LOOM MOTION Loom Primary Motion Secondary Motion Tertiary Motion Primary motion 1Shedding: (Tappet (Dobby. (Jacquard. 2Picking: (Over pick (Under pick. (Modern pick. 3Beating: (Single (Multiple (Variable. Secondary Motion 1. Take up a) Positive b) Negative. 2. Let off a) Positive b) Negative. (5 wheel, 7 wheel) Tertiary Motion 1 Warp stop motion 2Weft stop motion (Centre, side) 3 Reed stop motion (Loose, fast) 4 Temple motion (Roller, reed) 5 Weft replenish

- 46. Difference between Hand Loom and Power Loom Hand Loom 1.Operating system is manual. 1.Shedding is done by paddle and Picking, Beating is done by hand. 1.Less production. 1.Slow running speed. 1.Check and striped fabrics are produced. Power Loom 1.Operating by electric power. 1.Shedding and Picking is done automatically. 1.High production. 1.High running speed. 1.One color fabrics is produced.

- 47. Difference between Hesian and Sacking Loom Sacking Loom 1.Two up one down weave. plain Hesian Loom 1.One up one down weave. 1.It has two heald shafts. 1.No of tappet 2. 1.No auxiliary shaft. twill 1.It has 3 eald shafts. 1.No of tappet 3 1.Need of auxiliary shaft due to more 2 tappet is called counter shaft. 1.Two yarns are passed through a heald eye. 1.More spacing between warp yarns. 1.Coarser thread is used. 1.A single yarn is passed through a heald eye. 1.Less spacing between warp yarns. 1.Finer thread is used.

- 48. DEFINITION Knitting is the method of creating fabric by transforming continuous strands of yarn a series of interlocking loops, each row of such loop hanging by the one immediately preceding it. The basic element of knit fabric structure is the loop intermeshed with the loops adjacent to it on both side and above and bellows it.

- 49. TERMS ➢Kink of Yarn: Per loop from a single yarn. ➢Knitted Loop: two loops intermeshed. ➢Knitted Stitch: Three loops intermeshed. ➢ Top Arc: Loop Head ➢ ➢ ➢ ➢ ➢ Bottom Half Arc Leg/ Side Limber Needle Loop Sinker Loop Close Loop Open Loop

- 50. • Wale: Vertical column of needle loop. • Course: Horizontal row of needle loop. ➢Stitch Density: Wales per Inch × Course per Inch. ➢Stitch length: Needle loop + Sinker loop •Extended sinker loop ➢Face loop • Back loop Independent Needle Needle: United Needle Knitting M/C: there are three types of knitting M/C – 1. Warp knitting: Gives vertical movement of yarn. 2. Weft knitting: Gives horizontal movement of yarn. 3. Other loop forming and combined M/C: Tri-axial.

- 51. ➢Needle Carrier: Which carries needle. ➢Number of Feed System: The number of feeder by course. ➢Working Diameter: In circular knitting m/c, the distance from one needle exact to the other needle is known as working dia. ➢Working Width: In flat knitting m/c, the distance from first needle to the last needle is known as working width. ➢Gauge: Number of needle per inch. ➢Pitch: The distance the center from one needle to the center of another needle is known as pitch. There Are Three Types Of Knitted Fabric 1. Selvage fabric 2. Cut edge fabric 3. Tubular fabric

- 52. • Open lap • Close lap ➢Over lap ➢Under lap O = over lap U = under lap

- 53. MECHANICAL PRINCIPAL OF KNITTING TECHNOLOGY Basic Elements of Knitting 1. Needle 2. Sinker 3. Cam 1. NEEDLE: There are various types of needle are available in market which can be divided in the following group. a. Spring Bearded Needle b. Latch Needle c. Compound Needle

- 56. 2. SINKER

- 57. FUNCTION OF SINKER There are three function of sinker. 1. Loop formation 2. Holding down 3. Knocking over 1.Loop Formation: On bearded needle weft knitting machines of straight bar frame and sinker wheel type, the loop forming action is performed. The purpose of a sinker is to kink the newly laid yarn into loop as its forward edge of advance between two adjoining needle. 2.Holding down Sinker: The second function is hold down the old loop a lower level on the needle stem, then the new loop which are being formed and prevent to old loops from being lifted as the needles rise to clear from their hooks. 3.Knocking Over Sinker: The third function of the sinker is to knock over the old loops on the neck of the new loops.

- 58. 3. CAM The knitting cams are hardened steels and they are the assembly of different cam plates so that a track for butt can be arranged. Each needle movement is obtained by means of cams acting on the needle butts. The knitting cams are divided in to three groups. Such as 1. Knit cam 2. Tuck cam 3. Miss cam

- 60. Knitting Action of Latch Needle of Knit Loop 1. Rest Position 2. Tuck Position 3. Clearing Position 4. Feed Position 5. Custom Position 6. Knock over Position

- 61. Knitting Action for Tuck Loop in Latch Needle

- 62. Knitting Action of Spring Bearded Needle (Knit Loop)

- 63. PRIMARY BASIC STRUCTURES Knitting Fabric Structure 1. Plain structure 2. Rib structure 3. Interlock structure 4. Purl structure 1. PLAIN STRUCTURE Plain is produce by the needles setting as a single set, drawing the loops from technical back and towards the technical face side of the fabric. Example: jersey blister, jersey lily, stockinet etc. 2. RIB STRUCTURE The structure which requires 2 sets of needle operating in between each other so that Wales of face side and Wales of back sides are knitting on each side of fabric is called rib structure.

- 64. Features of Plain Single Jersey Fabric 1. Used only one set of needle to produce fabric. 2. Simplest and most economical production. 3. 40% potential recovery stretching. 4. Probability of carling of yarn. 5. Technical face is smooth and v-shape can be seen through the Wales. 6. Technical back is rough and wave shape appeared at the back thought the course. 7. If one yarn breaks, the needle loops successively unmosh through course, this effect is called laddering. 8. Unroving of yarn can be prevented by binding off.

- 65. Features of Plain Circular Knitting M/C 1. Single jersey is produce by plain circular knitting m/c. 2. One set of latch needle is used here. 3. Latch needle, sinker, cylinder, sinker ring revolve around the knitting cam system. stationary 4. Yarn supplied from cone placed either on or integral overhead bobbin stand or on a free standing side creel through tensioner, stop motion. Guide eyes down to the yarn guide. 5. Stationary yarn feeder are situated at a regular interval around the circumference of the cylinder. 6. The fabric in tubular form is drawn downward from inside the needle cylinder by tension roller and is wound onto the fabric batching roller of winding frame. 7. The winding down mechanism revolves along with the fabric tube. 8. As the sinker cam plate is placed outside on the needle circle, the centerof the cylinder is open and the m/c is referred as open top or sinker top m/c.

- 66. Features of Rib Structure 1. It is normally knitting with 2 sets of latch needle. 2. Rib has vertical card appearance. 3. 1×1 rib has the appearance of technical face of in fabric. 4. Released 1×1 rib is theoretically twice as thick and 1/2 the width of an equivalent plain fabric. 5. It is more expensive fabric to produce than plain. 6. It can be unravel from the end knitted last by the free loops head through to the back of each stitch. 7. It is a heavier structure. 8. It has no curling tendency. 9. Rib structures are elastic, form fitting and retain warmth better then plain structure.

- 67. Uses: Rib is suitable particularly for the top of the socks, cuff, collar rib border of garments, gloves etc. FEATURES OF CIRCULAR RIB M/C 1. In this m/c, one sides of needle is arranged vertically in the in the cylinder and another set of needle is arranged in the dial of the m/c. 2. Here both dial and cylinder rotates where cam with yarn feeder remain stationary. 3. The needle of dial and cylinder are arranged in different position alternatively. 4. No sinker is required for this m/c. 5. Not more than 2 cam tracks are possible for dial of this m/c. 3. FEATURES OF INTERLOCKING STRUCTURE 1. Interlocking has the technical face fabric as both sides. 2. Interlocking course requires 2-feeder per course. 3. Reverse loop cannot be seen. 4. Interlocking relaxes by about 30-40% on more compared with its knitting width. 5. This is balance, smooth, stable, structure. 6. Fabric is thickener, heavier, and narrower then rib of equivalent gauge. 7. Finer, better, more expensive yarn is required. 8. Bath horizontal and vertical stripe can be produced. 9. Production is lass.

- 68. 4. FEATURE OF PURL STRUCTURE 1. It has the similar appearance to pearl droplets. 2. Purl structure have one or more Wales which contain both and back loop-. 3. Both sides’ needle and sinker loops are prominent. 4. The thick of the two needle bed in purl m/c. 5. Double ended batch needles are used in purl m/c. 6. To types of m/c is available for purl structure. a) Flat m/c b) Circular m/c 7. The simple purl structure is 1×1 purl. 8. Purl fabric is twice as thick as plain fabric.

- 69. KNITTING ACTION OF RIB CIRCULAR M/C

- 71. Knitting Calculation No. of feeder = No. of cam = No. of course. No. of sinker = No. of needle = No. of loop = π D’’ G mm Number of needle = m Π D’’ G × l 1000 = m Π D’’ G l ×N ×F 1000 Π D’’ G l ×N ×F ×T = gm. 1000×1000 Production = Π D’’ G l ×N ×F ×T × 60 × 8 kg/shift 1000×1000 × 1000 Here, D’’ = cylinder dia G = gauge L = stitch length F = No. of feeder T = tex number

- 72. For single jersey: Production in weight, RPM of Cylinder × No. of feeder × π × Cylinder dia × gauge × loop length (mm) × Tex × 60 × 8 × efficiency % = kg/shift 1000 × 1000 × 1000 Production in length, CPM CPI = yards/shift RPM of cylinder × No of feeder × 60 × 8 × efficiency % CPI × 36 Production in length = yds/shift For Double Jersey Single jersey production in length 2 Production in weight = Single jersey production in weight × 2 kg/shift

- 73. Math-1 Given, CPI = 66 Cylinder dia = 25’’ Cylinder RPM = 20 Loop length = 2.2 mm Yarn count = 70 tex Gauge = 22 No. of feeder = 90 Efficiency =90 % Find the production of the m/c in weight and production in length. (Both single and double jersey)

- 74. PROOF Here, GSM = lb/inc2 W × C × l 25.4 × 36 × 840 × Ne W × C × l = lb/inch2 768096 × Ne 1m= 39.37 inch. 1 inch= 1/39.37 1 lb= 453 gm = × gm/m2 W × C × l 768096 × Ne 453 1 39.37 2 = × 453 × (39.37)2 W × C × l 768096 × Ne W × C × l = × 702148.5957 gm/m2 768096 × Ne = gm/m2 W × C × l ×0.915 Ne