Additive Manufacturing Guide

- 2. 1.1 INTRODUCTION TO ADDITIVE MANUFACTURING Additive manufacturing (AM) is the process of joining materials to make objects from Computer Aided Design (CAD) model data, usually layer upon layer, as opposed to subtractive manufacturing methods . Additive manufacturing is also called as 3D printing, additive fabrication, or freeform fabrication. These new techniques, while still evolving, are projected to exert a profound impact on manufacturing. They can give industry new design flexibility, reduce energy use, and shorten time to market. The current steps in AM are developing a 3-D model using a computer modeling software and converting the model into a standard AM file format, changing the size, location, or other properties of the model using AM software, then building the part in layers using the AM device.

- 3. DEFINITION Additive Manufacturing (AM) refers to a process by which digital 3D design data is used to build up a component in layers by depositing material. The term AM encompasses many technologies including subsets like 3D Printing, Rapid Prototyping (RP), Direct Digital Manufacturing (DDM), layered manufacturing and additive fabrication. AM application is limitless. Early use of AM in the form of Rapid Prototyping focused on preproduction visualization models. More recently, AM is being used to fabricate end-use products in aircraft, dental restorations, medical implants, automobiles, and even fashion products.

- 5. Basic structure of additive manufacturing and its subcategories

- 9. Additive vs Subtractive Manufacturing

- 10. Cont’d

- 11. Evolution of AM Technologies

- 13. Current and Potential industries for Additive Manufacturing

- 14. Latin term, "pro et contra", is the origin of the 'pros and cons' terms which means for or against. Pros do mean for, or in favor of, while cons is for against. Generally, pros and cons is taken as a method of decision making but do have other meanings also. Pros and Cons of AM

- 15. AM Benefits: Weight Reduction

- 16. AM Benefits: Customized Medical Products

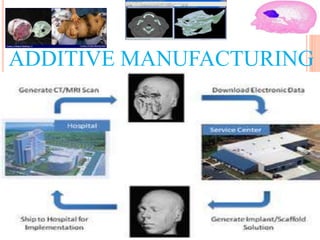

- 20. Data path for additive manufacturing

- 21. Generation of Geometrical Layer Information on Single Layers To produce three-dimensional models by layer-oriented additive manufacturing processes, the 3D CAD solid must be mathematically split into the same layers as those produced physically by the AM machine. This process is known as "slicing." There are two basic methods of doing this: 1) Triangulation, which leads to the STL format. 2) Direct cutting in the CAD system, which leads to the CL (SLI) format.

- 22. STL format STL is a file format native to the stereo lithography CAD software. It is widely used for rapid prototyping, 3D printing and computer-aided manufacturing. The main purpose of the STL file format is to encode the surface geometry of a 3D object. It encodes this information using a simple concept called "tessellation". Tessellation Tessellation is the process of tiling a surface with one or more geometric shapes such that there are no overlaps or gaps. Tessellation can involve simple geometric shapes or very complicated (and imaginative) shapes.

- 23. Classication of Additive Manufacturing Systems

- 24. 1. Liquid Based Additive Manufacturing Systems Building material is in the liquid state. The following AM Systems fall into this category: 1) Stereo lithography Apparatus(SLA) 2) Poly Jet 3D printing 3) Multi jet Printing(MJP) 4) Solid Object Ultra voilet-Laser Printer(SOUP) 5) Rapid Freeze Prototyping 2. Solid Based Additive Manufacturing Systems Building material is in the Solid state (except powder). The solid form can include the shape in the forms of wire, rolls, laminates and pellets. I The following AM Systems fall into this category: 1) Fused deposition modeling (FDM) 2) Selective Deposition Lamination (SDL) 3) Laminated Object Manufacturing (LOM) 4) Ultrasonic Consolidation

- 25. Powder Based Additive Manufacturing Systems Building material is Powder(grain like form). All Powder Based AM Systems employ the joining/binding method. The following AM Systems fall into this category: 1) Selective Laser Sintering(SLS) 2) ColorJet Printing(CJP) 3) Laser Engineered Net Shaping (LENS) 4) Electron Beam Melting(EBM) etc.

- 26. Liquid-Based Liquid-based RP systems have the initial form of its material in liquid state. Through a process commonly known as curing, the liquid is converted into the solid state. The following RP systems fall into this category: (1) 3D Systems’ Stereolithography Apparatus (SLA) (2) Cubital’s Solid Ground Curing (SGC) (3) Sony’s Solid Creation System (SCS) (4) CMET’s Solid Object Ultraviolet-Laser Printer (SOUP) (5) Autostrade’s E-Darts (6) Teijin Seiki’s Soliform System. (7) Meiko’s Rapid Prototyping System for the Jewelry Industry Three methods are possible under the “Photo-curing” method. The single laser beam method is most widely used and include all the above RP systems with the exception of (2), (11), (13) and (14). Cubital (2) and Light Sculpting (11) use the masked lamp method, While the two laser beam method is still not commercialized.

- 27. Except for powder, solid-based RP systems are meant to encompass all forms of material in the solid state. In this context, the solid form can include the shape in the form of a wire, a roll, laminates and pellets. The following RP systems fall into this definition: (1) Cubic Technologies’ Laminated Object Manufacturing (LOM) (2) Stratasys’ Fused Deposition Modeling (FDM) (3) Kira Corporation’s Paper Lamination Technology (PLT) (4) 3D Systems’ Multi-Jet Modeling System (MJM) (5) Solidscape’s ModelMaker and PatternMaster (6) Beijing Yinhua’s Slicing Solid Manufacturing (SSM), Melted Extrusion Modeling (MEM) and Multi-Functional RPM Systems (M- RPM) Solid-Based Two methods are possible for solid-based RP systems. RP systems (1), (3) & (4) belong to the Cutting and Glueing/Joining method, While the Melting and Solidifying/Fusing method used RP systems (2), (5) & (6),

- 28. The following RP systems fall into this definition: (1) 3D Systems' Selective Laser Sintering (SLS) (2) EOS’s EOSINT Systems (3) Z Corporation’s Three-Dimensional Printing (3DP) (4) Optomec’s Laser Engineered Net Shaping (LENS) (5) Soligen’s Direct Shell Production Casting (DSPC) (6) Fraunhofer’s Multi phase Jet Solidification (MJS) (7) Acram’s Electron Beam Melting (EBM) (8) Aeromet Corporation’s Lasform Technology Powder-Based In a strict sense, powder is by-and-large in the solid state. However, it is intentionally created as a category outside the solid-based RP systems to mean powder in grain-like form. All the above RP systems employ the Joining/Binding method. The method of joining/binding differs for the above systems in that some employ a laser while others use a binder/glue to achieve the joining effect.

- 29. Table 1 – The Seven AM Process Categories by ASTM F42

- 30. RAPID PROTOTYPING PROCESS 1. Create a CAD model of the design . 2. Convert the CAD model to STL format (STANDARD TRIANGULATION LANGUAGE). 3. Slice the STL file into thin cross-sectional layers. 4. Construct the model one layer atop another. 5. Clean and finish the model.

- 32. RAPID PROTOTYPING PROCESS STEP 1: CAD Model Creation First, the object to be built is modeled using a Computer-Aided Design (CAD) software package. Solid modelers, such as Pro/ENGINEER, tend to represent 3-D objects more accurately than wire-frame modelers such as AutoCAD, and will therefore yield better results. This process is identical for all of the RP build techniques. STEP 2: CONVERSION TO STL FORMAT The second step, therefore, is to convert the CAD file into STL format. This format represents a three-dimensional surface as an assembly of planar triangles. To establish consistency, the STL format has been adopted as the standard of the rapid prototyping industry.

- 35. The standard data interface between CAD software and the machines is the STL file format. • An STL file approximates the shape of a part or assembly using triangular facets. •Smaller facets produce a higher quality surface. •SLC: Slice format, CLI: Common Layer Interface

- 36. RAPID PROTOTYPING PROCESS STEP 3: SLICE THE STL FILE In the third step, a pre-processing program prepares the STL file to be built. The pre-processing software slices the STL model into a number of layers from 0.01 mm to 0.7 mm thick, depending on the build technique. The program may also generate an auxiliary structure to support the model during the build. Supports are useful for delicate features such as overhangs, internal cavities, and thin-walled sections. STEP 4: LAYER BY LAYER CONSTRUCTION The fourth step is the actual construction of the part. RP machines build one layer at a time from polymers, paper, or powdered metal. Most machines are fairly autonomous, needing little human intervention.

- 37. RAPID PROTOTYPING PROCESS STEP 5: CLEAN AND FINISH The final step is post-processing. This involves removing the prototype from the machine and detaching any supports. Some photosensitive materials need to be fully cured before use. Prototypes may also require minor cleaning and surface treatment. Sanding, sealing, and/or painting the model will improve its appearance and durability.

- 40. Stereo lithography One of the most important additive manufacturing technologies currently available. The first ever commercial RP systems were resin-based systems commonly called stereo lithography or SLA. The resin is a liquid photosensitive polymer that cures or hardens Stereo lithography when exposed to ultraviolet radiation. This technique involves the curing or solidification of a liquid photosensitive polymer through the use of the irradiation light source. The source supplies the energy that is needed to induce a chemical reaction (curing reaction), bonding large no of small molecules and forming a highly cross-linked polymer

- 42. SLA 3D Printing Product

- 44. Prototyping or model making is one of the important steps to finalize a product design. It helps in conceptualization of a design. Before the start of full production a prototype is usually fabricated and tested. The term rapid prototyping (RP) refers to a class of technologies that can automatically construct physical models from Computer-Aided Design (CAD) data. Rapid prototyping is the automatic construction of physical objects using solid freeform fabrication and are used to produce model and prototype parts. Rapid prototyping takes virtual designs, transforms them into cross sections, still virtual, and then create each cross section in physical space, one after the next until the model is finished. In product development, time pressure has been a major factor in determining and direction of the development and success of new methodologies & techniques for enhancing its performance. INTRODUCTION

- 45. Rapid prototyping technology is a group of manufacturing processes that enable the direct physical realization of 3D computer models. This technology converts the 3D computer data provided by a dedicated STL file format to physical model , layer by layer with a high degree of accuracy. The standard data interface b/w CAD software and the machine is the STL file format. A STL file approximates the shape of a part or assembly using triangular facets , that tiny facets produces a higher quality surfaces. The machine reads data from a CAD drawing and lays down successive layer of liquid, powder or sheet material and this way builds up the model from a series of cross sections. These layer, which correspond to the virtual cross section in the CAD model, are joined together or fused automatically to create the final shape.

- 46. Rapid Prototyping (RP) Rapid Prototyping (RP) can be defined as a group of techniques used to quickly fabricate a scale model of a part or assembly using three-dimensional computer aided design (CAD) data. A family of unique fabrication processes developed to make engineering prototypes in minimum lead time based on a CAD model of the item. The traditional method is machining (time consuming) RP allows a part to be made in hours or days rather than weeks, given that a computer model of the part has been generated on a CAD system

- 47. Why Rapid Prototyping Because product designers would like to have a physical model of a new part or product design rather than just a computer model or line drawing Creating a prototype is an integral step in design A virtual prototype may not be sufficient for the designer to visualize the part adequately Using RP to make the prototype, the designer can visually examine and physically feel the part and assess its merits and shortcomings.

- 48. Needs For Prototyping: The extreme usage of complicated shapes and availability of limited resources led the way to development of things field of manufacturing methodology. •To increase effective communication. •To decrease development time. •To decrease costly mistakes. •To minimize sustaining engineering changes. •To extend product lifetime by adding necessary features and eliminating redundant features early in the design. •Takes less time to design and manufacture. •Meets customer demand. • Creating a prototype is an integral step in design.

- 49. A virtual prototype may not be sufficient for the designers to visualize the part adequately. Using RP to make the prototype, the designers can visually examine and physical feel the part and asses the merits and demerits. Rapid Prototyping decreases development time by allowing corrections to a product to be made early in the process. The trends in manufacturing industries continue to emphasize the following: Increasing number of variants of products. Increasing product complexity.

- 50. HISTORY DEVELOPMENT OF RP SYSTEM Development •Manual Prototyping by craftsman •1970 prototyping in CAD , virtual environment •1980, Rapid Prototyping (RP) by layer-by-layer material deposition. CAD/CAM FUNDAMENTALS OF RAPID PROTOTYPING Common to all the different techniques of RP is the basic approach they adopted. A model or component is modeled on a Computer-Aided Design/ Computer-Aided Manufacturing (CAD/CAM) system. The model which represents the physical part to be built must be represented as closed surfaces which unambiguously define an enclosed volume.

- 51. STL” (Standard triangulation language ) file format which originates from 3D Systems. The STL file format approximate surfaces of the model by polygons. Highly curved surfaces must employ many polygons, which means that STL files for curved parts can be very large. Ex: IGES (Initial Graphics Exchange Specifications) data. A computer program analyzes a STL file that defines the model to be fabricated and “slices” the model into cross sections. The cross sections are systematically recreated through the solidification of either liquids or powders and then combined to form a 3D model.

- 52. Fundamentally, the development of RP can be seen in four primary areas.

- 53. Input Input refers to the electronic information required to describe the physical object with 3D data. There are two possible starting points a computer model or a physical model. The computer model created by a CAD system can be either a surface model or a solid model. On the other hand, 3D data from the physical model is not at all straightforward. It requires data acquisition through a method known as reverse engineering. In reverse engineering, a wide range of equipment can be used, such as CMM (coordinate measuring machine) or a laser digitizer, to capture data points of the physical model and “reconstruct” it in a CAD system.

- 54. Method While they are currently more than 20 vendors for RP systems, the method employed by each vendor can be generally classified into the following categories: photo-curing, cutting and glueing/joining, melting and solidifying/fusing and joining/binding. Photo-curing can be further divided into categories of single laser beam, double laser beams and masked lamp. Material The initial state of material can come in either solid, liquid or powder state. In solid state, it can come in various forms such as pellets, wire or laminates. The current range materials include paper, nylon, wax, resins, metals and ceramics.

- 55. Most of the RP parts are finished or touched up before they are used for their intended applications. Applications can be grouped into (1) Design (2) Engineering, Analysis, and Planning and (3) Tooling and Manufacturing. A wide range of industries can benefit from RP and these include, but are not limited to, aerospace, automotive, biomedical, consumer, electrical and electronics products. Applications

- 56. THREE PHASES OF DEVELOPMENT LEADING TO RAPID PROTOTYPING First Phase: Manual Prototyping Prototyping had began as early as humans began to develop tools to help them live. However, prototyping as applied to products in what is considered to be the first phase of prototype development began several centuries ago. In this early phase, prototypes typically are not very sophisticated and fabrication of prototypes takes on average about four weeks, depending on the level of complexity and representativeness Example: Prototypes tend to be craft-based.

- 57. Parallels between geometric modeling and prototyping

- 59. Second Phase: Soft or Virtual Prototyping The early 1980s saw the evolution of the second phase of prototyping — Soft or Virtual Prototyping. Virtual prototyping takes on a new meaning as more computer tools become available — computer models can now be stressed, tested, analyzed and modified as if they were physical prototypes. For example, analysis of stress and strain can be accurately predicted on the product because of the ability to specify exact material attributes and properties.

- 60. Third Phase: Rapid Prototyping Rapid Prototyping of physical parts, or otherwise known as solid freeform fabrication or desktop manufacturing or layer manufacturing technology, represents the third phase in the evolution of prototyping. The invention of this series of rapid prototyping methodologies is described as a “watershed event” because of the tremendous time savings, especially for complicated models. Though the parts (individual components) are relatively three times as complex as parts made in 1970s, the time required to make such a part now averages only three weeks . Since 1988, more than twenty different rapid prototyping techniques have emerged.

- 62. CLASSIFICATION OF RAPID PROTOTYPING

- 63. Methods of Prototyping: There are two main methods of prototyping, which are derived from similar approaches in sculpture. •Subtractive prototyping •Additive prototyping Subtractive process:. In this technique the machine starts out with a block of plastic and uses a delicate cutting tool to carve away material, layer by layer to match the digital object. They may start with a block, sheet, or tube of raw material and then, by drilling, cutting, lathing or by grinding; the material is removed, yielding the desired object or product. This is similar to a computer-controlled lathe. This is earlier and less efficient. Additive process: The desired object is built from bottom to top in very thin layers. Whereas subtractive techniques require hard-earned craft skills for the complicated and unique setups that vary with each job, additive techniques require no special knowledge on the part of the prototype fabricator.

- 64. Rapid prototyping is an additive process . Today's additive technologies offer advantages in many applications compared to classical subtractive fabrication methods such as milling or turning, they are: Objects can be formed with any geometric complexity or intricacy without the need for elaborate machine setup or final assembly; Rapid prototyping systems reduce the construction of complex objects to a manageable, straightforward, and relatively fast process.

- 68. Advantages during development ... No tooling costs •Short production times •Comparatively low unit prices •Constructional simplification: e.g. instead of housing, lid and screws, 1 complete sintered unit can be made •Test- and functional products can be produced in small batches •Formal- and functional variants possible

- 69. Engineering Analysis and Planning Existence of part allows certain engineering analysis and planning activities to be accomplished that would be more difficult without the physical entity Comparison of different shapes and styles to determine aesthetic appeal Wind tunnel testing of streamline shapes Stress analysis of physical model Fabrication of pre-production parts for process planning and tool design Design benefits of RP: Reduced lead times to produce prototypes Improved ability to visualize part geometry Early detection of design errors Increased capability to compute mass properties

- 70. Problems with Rapid Prototyping Part accuracy: Staircase appearance for a sloping part surface due to layering . Shrinkage and distortion of RP parts. Limited variety of materials in RP Mechanical performance of the fabricated parts is limited by the materials that must be used in the RP process

- 71. ... production ... No tooling costs for small- and medium-sized batches Low tooling costs for larger batches Product customization possible without additional costs ... and the production of spare parts. No tooling management necessary Spare parts need no longer be kept but produced as required Unlimited subsequent delivery Builds complex 3D geometrical shapes Is automated based on CAD models Uses a generic fabrication machine that does not require part specific tooling Requires a minimum of or no human intervention Produces accurate prototypes in a short time at a minimum cost

- 72. TYPES OF RAPID PROTOTYPING PROCESS Stereolithography (SLA) . Selective Laser Sintering (SLS®) . Laminated Object Manufacturing (LOM™) . Fused Deposition Modeling (FDM) . Solid Ground Curing (SGC) . Ink Jet printing / 3D PRINTERS .

- 73. STEREOLITHOGRAPHY PROCESS Stereolithography (SLA), the first Rapid Prototyping process, was developed by 3D Systems of Valencia, California, USA, founded in 1986. RP process for fabricating a solid plastic part out of a photosensitive liquid polymer using a directed laser beam to solidify the polymer Part fabrication is accomplished as a series of layers - each layer is added onto the previous layer to gradually build the 3-D geometry The first addition RP technology - introduced 1988 by 3D Systems Inc. based on the work of Charles Hull More installations than any other RP method .

- 74. The SLA process is based fundamentally on the following principles Parts are built from a photo-curable liquid resin that cures when exposed to a laser beam (basically, undergoing the photo polymerization process) which scans across the surface of the resin. The building is done layer by layer, each layer being scanned by the optical scanning system and controlled by an elevation mechanism which lowers at the completion of each layer. Stereolithography (SL) is an additive manufacturing technology for producing models, prototypes, patterns, and in some cases, production parts. UV laser and liquid photo curable resin . Laser cures resin .

- 75. CONTINUED…. A vat of photosensitive resin contains a vertically-moving platform. The part under construction is supported by the platform that moves downward by a layer thickness (typically about 0.1 mm / 0.004 inches) for each layer. A laser beam traces out the shape of each layer and hardens the photosensitive resin. can be used as master patterns for injection molding, thermoforming, blow molding, and also in various metal casting processes

- 80. SLA 250/50HR SLA 3500 SLA5000 SLA7000 Lasertype, HeCd,325nm, Solid state Solid state Solid state wavelength, 6mW Nd:YVO4 frequency frequency power 354.7nm tripled tripled 160mW Nd:YVO4 Nd:YVO4 354.7nm 354.7nm 216mW 800mW Layer thickness 0.0625-0.1 0.05-0.1 0.05-0.1 0.0254-0.127 Mm Beam diameter 0.06-00.08 0.20-0.30 0.20-0.30 0.23-0.28 to mm 0.685-0.838 Drawing speed 635 mm/s 3.45 m/s Up to 5.0 m/s 2.54-9.52 m/s Max part weight, 9.1 56.8 68.04 68.04 Kg Elevator 0.0025 0.00177,+/- 0.00177,+/- 0.001,+/- resolutionand 0.005 0.013 0.001 repeatability mm Vat capacity,L 32.2 99.3 253.6 253.6 Department of Mechanical Engineering, DBIT, Bengaluru. Page 10 PROCESS PARAMETERS

- 81. Max build 250 x 250 x 250 350 x 350 x 508 x 508 x 508 x 508 x envelop ,mm 400 584 600 Operating system MS-DOS WINDOWS WINDOWS WINDOWS NT NT NT Weight kg 461 1100 1363 1455 PROCESS PARAMETERS 1. UV LASER BEAM. 2. PHOTO CURABLE LIQUID RESIN. 3. LASER SCANNING. 4. ELEVATORS. 5. PHOTO POLYMERIZATION PROCESS.

- 82. Advantages: Possibility of manufacturing parts which are impossible to be produced conventionally in a single process. Can be fully automated and no supervision is required. High Resolution. No geometric limitations. Good accuracy (approximately + 0.005 inches) Superior surface finish Able to use a wide range of materials Compatible with several color changing materials Widely available

- 83. Disadvantages: Necessity to have a support structure. Require labor for post processing and cleaning. Liquid materials tend to be messy . Parts produced may require a post-curing operation in a separate oven. Few materials compatible . Warpage and shrinkage issues . Require supports . Resin is expensive. Resins and solvents can be environmentally hazardous.

- 84. APPLICATION (1) Models for conceptualization, packaging and presentation. (2) Prototypes for design, analysis, verification and functional testing. (3) Parts for prototype tooling and low volume production tooling. (4) Patterns for investment casting, sand casting and molding. (5) Tools for fixture and tooling design, and production tooling.

- 85. Figure : Modeling jewelry on JCAD3/Takumi and MEIKO

- 86. Selective Laser Sintering (SLS®, registered trademark by DTM™ of Austin, Texas, USA) is a process that was patented in 1989 by Carl Deckard, a University of Texas graduate student. With the financial support from the BF Goodrich Company, and based on the technology that was developed and patented at the University of Texas at Austin, the company shipped its first commercial machine in 1992. DTM had worldwide exclusive license to commercialize the SLS® technology until they were bought over by 3D Systems in August 2001. 3D Systems’ head office address is 26081 Avenue Hall, Valencia, CA91355, USA

- 87. SLS PRINCIPLES (1) Parts are built by sintering when a CO2 laser beam hits a thin layer of powdered material. The interaction of the laser beam with the powder raises the temperature to the point of melting, resulting in particle bonding, fusing the particles to themselves and the previous layer to form a solid. (2) The building of the part is done layer by layer. Each layer of the building process contains the cross-sections of one or many parts. The next layer is then built directly on top of the sintered layer after an additional layer of powder is deposited via a roller mechanism on top of the previously formed layer.

- 88. Sinter Bonding particles in each successive layer are fused to each other and to the previous layer by raising their temperature with the laser beam to above the glass-transition temperature. The glass-transition temperature is the temperature at which the material begins to soften from a solid to a jelly-like condition. As a result, the particles begin to soften and deform owing to their weight and cause the surfaces in contact with other particles. One major advantage of sintering over melting and fusing is that it joins powder particles into a solid part without going into the liquid phase, thus avoiding the distortions caused by the flow of molten material during fusing. This high laser power requirement can be reduced by using auxiliary heaters at the powder bed to raise the powder temperature to just below the sintering temperature during the sintering process. However an inert gas environment is needed to prevent oxidation or explosion of the fine powder particles.

- 91. SLS PROCESS The SLS® process creates three-dimensional objects, layer by layer, from CAD-data generated in a CAD software using powdered materials with heat generated by a CO2 laser within the Vanguard TM system. CAD data files in the STL file format are first transferred to the Vanguard TM system where they are sliced. (1) A thin layer of heat-fusible powder is deposited onto the part building chamber. (2) The bottom-most cross-sectional slice of the CAD part under fabrication is selectively “drawn” (or scanned) on the layer of powder by a heat-generating CO2 laser. The interaction of the laser beam with the powder elevates the temperature to the point of melting, fusing the powder particles to form a solid mass. The intensity of the laser beam is modulated to melt the powder only in areas defined by the part’s geometry. Surrounding powder remain a loose compact and serve as supports.

- 92. (3) When the cross-section is completely drawn, an additional layer of powder is deposited via a roller mechanism on top of the previously scanned layer. This prepares the next layer for scanning. (4) Steps 2 and 3 are repeated, with each layer fusing to the layer below it. Successive layers of powder are deposited and the process is repeated until the part is completed.

- 93. MATERIALS OF SLS PROCESS Polyamide. Trade named “DuraFormTM”, this material is used to create rigid and rugged plastic parts for functional engineering environments. This composite material improves the resistance to heat and chemicals. Thermoplastic elastomer. Flexible, rubber-like parts can be prototyped using the SLS. Trade named, “SOMOS® 201”, It is able to resist abrasion and provides good part stability. The material is impermeable to water and ideal for sports shoe applications and engineering seals. Polycarbonate. An industry-standard engineering thermoplastic. These are suitable for creating concept and functional models and prototypes, investment casting patterns for metal prototypes and cast tooling (with the Rapid CastingTM process), masters for duplication processes, and sand casting patterns

- 94. Nylon. Another industry-standard engineering thermoplastic. This material is suitable for creating models and prototypes that can withstand and perform in demanding environment. It is durable, resistant to heat and chemicals, and is excellent when fine detail is required Metal. This is a material where polymer coated stainless steel powder is infiltrated with bronze. Trade named “Laser Form ST-100”, material is excellent for producing core inserts and preproduction tools for injection molding prototype polymer parts. Ceramics. Trade named “SandFormTM Zr” and “SandformTM Si”, these use zircon and silica coated with phenolic binder to produce complex sand cores and molds for prototype sand castings of metal parts

- 95. PROCESS PARAMETER LASER RELATED PARAMETERS ( Laser power, spot size, pulse duration, pulse frequency) SCAN RELATED PARAMETERS (scan speed, scan spacing, scan pattern) POWER RELATED PARAMETERS ( particle size, shape and distribution, powder bed density, layer thickness, material properties ) TEMPARATURE RELATED PARAMETERS ( power bed temperature, power feeder temperature, temperature uniformity )

- 97. MACHINE SPECIFICATION A) SINTER STATION 2500PLUS

- 99. ADVANTAGES Advanced software support. No post-curing required. Little post-processing required. No part supports required. Wide range of processing materials. Good part stability. Parts and/or assemblies that move and work that have a good surface finish and feature details. Selective laser sintering (SLS) gives the capability of flexible snaps and living hinges as well as high stress and heat tolerance. Wide variety of materials such as flexible and rigid plastics, electrometric materials, fully dense metals and casting patterns. Inexpensive materials. Safe materials. Supports not needed. Reduced distortion from stresses. Produce parts simultaneously.

- 100. DISADVANTAGES Large physical size of the unit. High power consumption. Poor surface finish. Rough surface finish ("stair step effect") Porosity of parts The first layers may require a base anchor to reduce thermal effects (e.g. curl) Part density may vary Material changes require cleaning of machine

- 101. APPLICATION concept modelers. Functional models and working prototypes. wax casting pattern. Polycarbonate pattern. Metal tools. Rover Applies SLS Process in Tooling for Injection Molding. Reebok Uses SLS Process for Developing Sports Shoes. Boeing Uses Prototyping to Maximize Return on Investment.

- 102. STRATASYS’ FUSED DEPOSITION MODELING (FDM) Stratasys Inc. was founded in 1989 and has developed most of the company’s products based on the Fused Deposition Modeling (FDM) technology. The technology was first developed by Scott Cramp in 1988 and the patent was awarded in the U.S. in 1992. FDM uses the extrusion process to build 3D models. Stratasys introduced its first rapid prototyping machine, the 3D modeler® in early 1992 and started shipping the units later that year.

- 103. PRINCIPLES The principle of the FDM is based on surface chemistry, thermal energy, and layer manufacturing technology. The material in filament(spool) form is melted in a specially designed head, which extrudes on the model. As it is extruded, it is cooled and thus solidifies to form the model. The model is built layer by layer, like the other RP systems. Parameters which affect performance and functionalities of the system are material column strength, material flexural modulus, material viscosity, positioning accuracy, road widths, deposition speed, volumetric flow rate, tip diameter, envelope temperature, and part geometry.

- 104. PROCESS

- 106. process RP process in which a long filament of wax or polymer is extruded onto existing part surface from a work head to complete each new layer . Work head is controlled in the x-y plane during each layer and then moves up by a distance equal to one layer in the z-direction. Extruded is solidified and cold welded to the cooler part surface in about 0.1 s . Part is fabricated from the base up, using a layer-by- layer procedure. A plastic filament or metal wire is unwound from a coil and supplies material to an extrusion nozzle which can turn on and off the flow. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism

- 107. The model or part is produced by extruding small beads of thermoplastic material to form layers as the material hardens immediately after extrusion from the nozzle. In this technique, filaments of heated thermoplastic are extruded from a tip that moves in the x-y plane. Like a baker decorating a cake, the controlled extrusion head deposits very thin beads of material onto the build platform to form the first layer. The platform is maintained at a lower temperature, so that the thermoplastic quickly hardens. After the platform lowers, the extrusion head deposits a second layer upon the first. Supports are built along the way, fastened to the part either with a second, weaker material or with a perforated junction. The fused disposition modeling process uses plastic filament that is 1/16” in diameter and stored on a coil.

- 109. PROCESS PARAMETERS FDM 2000 FDM 3000 FDM 8000 Quantum Build size mm 254 x 254 x 254 254 x 254 x 406 457 x 457 x 609 600 x 500 x 600 Accuracy mm +/- 0.127 +/- 0.127 +/- 0.127-0.254 +/- 0.127 Size mm 660x 914 x 1067 660 x 1067 x 1486 x 1905 x 2235 x 1981 x 914 1003 1118 Weight Kg 160 160 392 1134 Power 220-240 VAC 208-240 VAC 220-240 VAC 208-240 VAC requirements 50/60 Hz 10A 50/60 Hz 10A 50/60 Hz 10A 50/60 Hz 10A single phase single phase single phase single phase Materials ABS (white) ABS (white) ABS ABS Investment Investment casting wax casting wax Elastomer Elastomer Layer width 0.254 to 2.54 0.254 to 2.54 0.254 to 2.54 0.38 to 0.51 mm mm mm Layer thickness 0.05 to 0.762 0.05 to 0.762 0.05 to 0.762 0.18 to 0.25 mm mm mm mm

- 110. CON’TD.. Liquifier temperature. Chamber temparature. Stand off distance. Filament feed rate. Nozzle diameter. Deposition type. Layer thickness. Scanning speed of the laser. Row width.

- 111. MATERIALS Acrylonitrile butadiene styrene (ABS) polymer, the FDM technology can also be used with poly carbonates, polycaprolactone, polyphenyl sulfones and waxes.

- 112. ADVANTAGES True desktop manufacturing system that can be run in office environment. There is no worry of exposure to toxic fume and chemicals. The process is clean, simple, easy to operate and Fast building for bottle like structure or hollow parts Material is supplied in spool form which is easy to handle and can be changed in minute Materials used are very cost effective, typical parts cost under US$20 A good variety of material is available including colour ABS and Medical ABS, investment casting wax and elastomer Mid-range performance/cost RP system and is the bestselling RP system in 1995 It does not need laser systems, uses relatively inexpensive binders, and is easy to change materials.

- 113. DISADVANTAGE Accuracy is relatively low and is difficult To build parts with complicated details Poor strength in vertical direction Slow for building a mass part The main difficulties are in controlling temperature within the growing part, the need to provide support structures for the growing model The accuracy which is limited to the nozzle diameter.

- 114. APPLICATION FIG: Investment cast wax patterns for injection mold created using FDM