SNAMPROGETTI Urea Process Description

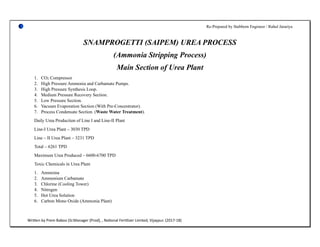

- 1. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) SNAMPROGETTI (SAIPEM) UREA PROCESS (Ammonia Stripping Process) Main Section of Urea Plant 1. CO2 Compressor 2. High Pressure Ammonia and Carbamate Pumps. 3. High Pressure Synthesis Loop. 4. Medium Pressure Recovery Section. 5. Low Pressure Section. 6. Vacuum Evaporation Section (With Pre-Concentrator). 7. Process Condensate Section. (Waste Water Treatment). Daily Urea Production of Line I and Line-II Plant Line-I Urea Plant – 3030 TPD Line – II Urea Plant – 3231 TPD Total – 6261 TPD Maximum Urea Produced – 6600-6700 TPD Toxic Chemicals in Urea Plant 1. Ammoina 2. Ammonium Carbamate 3. Chlorine (Cooling Tower) 4. Nitrogen 5. Hot Urea Solution 6. Carbon Mono Oxide (Ammonia Plant)

- 2. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) Process Description main process steps CO2 compression High pressure synthesis loop Medium pressure recovery section Low pressure section Vacuum evaportation section Process condensate section Description of the process The urea procution process takes place through the following main operations- Urea synthesis and high pressure recovery Urea purification and low pressure recovery Urea Concentration Urea Prilling Wastewater treatment Advantages of excess ammonia Avoids corrosion Promotes stripping Higher conversion Less biuret formation Flexibility in operation

- 3. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) Less passivation air Less severity in pumping High pressure synthesis loop CO2 compression Reaction of NH3 and CO2 Urea formation NH3/CO2 and H2O/CO2 molar ratio Decomposition of carbamate Low pressure steam production Urea synthesis and High pressure recovery: Urea is produced by synthesis from liquid ammonia and gaseous carbon dioxide, In the reactor 31/41 R-1, the ammonia and Carbon dioxide react to form ammonium carbamate, portion of which dehydrates to form Urea and water. Carbamate, portion of which dehydrates to form Urea and Water. The reactions are as follows, 2NH3 + CO2 = NH2COONH4 NH2COONH4 = NH2COONH2 + H2O In Synthesis, conditions (T – 188°C and P – 155 kg/cm2 ), the first reaction occure slowly and determines the reactor volume. The fraction of Ammonium carbamate that dehydrates is determined by the ratio of the various reactants, the operating temperature and residence time in the reaction.

- 4. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) Formation of biuret takes place when urea is heated to its melting point it starts decomposition with evolution of ammonia presumably, urea first isomerizes which dissociates into isocynic acid and ammonia. CO(NH2)2 = NH4CNO + NH3 Urea Ammonium cynate The isocynic acid reacts with urea to form biuret. NHCO + CO(NH2)2 = NH2CONHCONH2 In the presence of excess ammonia biuret is formed at substantially lower rate by direct reaction between urea molecules. 2CO(NH2)2 (Urea) = NH2CONHCONH2 (Biuret) + NH3 (ammonia) Biuret + Urea = Triuret (polymer) + Ammonia NH2CONHCONH2 (Biuret) + NH2CONH2 (Urea) = (H2NC(O)NH)2CO (Triuret) + NH3 (Ammonia) The mole ration of NH3 to CO2 is 3.3-3.6 The mole ratio of H2O to CO2 is 0.5 to 0.7 The total flow of liquid ammonia coming directly from the battery limits is measured by turbine flow meter FQR-106 and then diverted to 31- 41 unit. The flow of liquid ammonia going to each unit is measured by FIR 104 and temperature by TI-1-113 (12°C), is collected in the ammonia receiver tank 31-41 V-1. From V-1, it is drawn and compressed at about 22.4 kg/cm2 pressure absorber /41 C-1, the remaining part enters the high pressure synthesis loop. The ammonia feeding the synthesis loop is compressed by two – speed, heavy duty reciprocating pumps 31/41 P-1 A/B at a pressure of about 240 ata. Before entering the reactor the ammonia feed is used as motive fluid in the carbamate Ejector 31/41 EJ-1, where the carbamate coming from the Carbamate Separator 31/41 MV-1 is compressed up to the synthesis pressure. The liquid mixture of NH3 and carbamate enters the reactor where NH3 reacts with the compressed carbon dioxide. The co2 drawn at urea plant battery limits at about 1.5 ata and about 40°C enters the centrifugal compressor temperature 130°C is fed to urea reactor (31/41 R-1) though K-1 discharge separator (31-41 MV-8) A small quantity of air is added to the carbon dioxide at the compressor suction in order to passivate the stainless steel surfaces, thus protecting them for corrosion due to steam reagent and reaction product. The reaction products, leaving the reactor, flow to the steam heated falling film type stripper 31/41 E-1, which operates at 146 kg/cm2 g pressure stripping action of the ammonia as it boils out of the solution. For the bottom of bimetallic stripper, passivation air is required in continuous way. For this passivation air compressor

- 5. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) K-3A/B are installed. The carbamate decomposition heat is supplied by 24 ata saturated steam. The overhead gases and the recovered solution from M.P. absorber (C-1), all flow to the high pressure carbamate condensers (E-5) where the total absorber, except for a few inerts, is condensed and recycled to the reactor by means of ejector (EJ-1). The condensation of gases at high pressure and temperature permits the production of 4.5 ata steam in the high pressure carbamate condenser. In the carbamate separator (MV-1) the incondensable gases, consisting of inert gases containing a little quantity of NH3 and CO2 unreacted in the condenser, are separated from the carbamate solution and sent to the medium pressure decomposer (E-2). Urea high pressure section as following: Urea purificaton and low pressure recovery Urea purification takes place in two stages at decreasing pressure as follows: 1st stage at 18 ata pressure. 2nd stage at 4.5 at pressure. Medium pressure recovery section Carbonate decomposition CO2 absorption NH3 recovery NH3 pumping to 225 ata Carbonate pumping to 160 ata

- 6. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 7. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 8. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 9. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 10. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 11. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 12. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 13. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 14. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 15. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18)

- 16. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) NH3 make up from ammonia receiver (V-1) 1st Purification and recovery stage at 18 ata The solution leaving the existing urea Striper, after being let down in the level control valve, enters the vertical exchanger named pre- decomposer (E-53) where the decomposition of carbamate occurs by means of the hear supplied through boosted steam generated in steam booster ejector (Ej-53). This ejector utilize as motive fluid the MS saturated steam coming from stripper steam condensate separator (V-29). The sucked fluid is low pressure steam from the heater. The operating pressure at the discharge f the booster ejector is about 6.5 kg/cm2 (a) and the temperature about 161°C. Intake falling film type evaporator, E-52 where the low residual carbonate is decomposed and water is evaporated. The required heat is supplied by means of partial condensation (in shell side) of overhead gas coming from the M.P. decomposer. The required heat is supplied by means of partial condensation (in the shell side) of overhead gas coming from the MP Decomposer. Bottom liquid holder ME 52, where the urea solution at 83-84% wt is collected. The mixed phase leaving the pre-Decomposer enters the existing MP decomposer separator MV-2 where the gases are separated from the liquid which proceed to the MP decomposer for further decomposition. The solution with a residual CO2 content, leaving the bottom of the stripper is expanded at the pressure of 18 ata and enters the medium pressure pre decomposer (E-53) them MP decomposer E-2 (falling film type). This equipment is divided into two parts: Top separator MV-2 where the residual gases are removed flash gases are removed before the solution enters the tube bundle. Decomposition section where the residual carbamate is decomposed and the required heat is supplied by 24 ata steam condensate flowing out of the stripper. The top gases sent to be Pre Concentrator shell side for heating purpose. The NH3 & CO2 rich gases leaving the top separator, MV-2 are sent to the shell side of the falling film Pre-Concentrator, E-52, where they are partially absorbed in aqueous Carbonate solution coming from the LP recovery section via M.P. Carbonate solution Pump P-3 A/B. The total heat from the shell side, due to condensation/absorption/reaction of reagents , is removed by evaporating urea solution coming from the low pressure decomposer holder ME-3, up to 83-84% wt in pre-concentrator, thus allowing a considerable saving of L.P. Steam in the vacuum concentration stage. From the Pre-Concentrator, E-52 shell side the mixed phase is sent to the existing medium pressure condenser, E-7, where CO2 is almost totally absorbed and condensation/ reaction heat is removed by cooling water coming from ammonia condenser, E-9. This is mainly divided in the three parts:- Top separator MV-2 , where the released flash gases are removed before the solution enters the tube bundle, vapors are extracted by the Pre- Concentrator Vacuum System ME-51. The NH3 and CO2 rich gases leaving the top separator are sent to the medium pressure condenser (E- 7) where they are partially absorbed in aqueous carbamate solution coming from the low pressure recovery section via pump (P-3).

- 17. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) A tempered water circuit is provided to prevent carbamate solidification and to keep a suitable cooling water temperature at the medium pressure condenser inlet recirculating the cooling water by means of pump (P-4 A/B). In the condenser, CO2 is almost totally absorbed. The mixture from E-7 flows to the medium pressure absorber (C-1) where the gaseous phase coming from the solution enters the rectification section. This is of bubble cap trays type and preforms CO2 absorption and NH3 rectification. The trays are fed by pure reflux ammonia is which eliminates residual CO2 and H2O contained in the inters gases. Reflux ammonia is drawn from the Ammonia receiver (V-1) and sent to the column C-1 by means of centrifugal pump (P- 5A/B). A current of inert gases saturated with NH3 with some ppm of CO2 residue comes out from the top of the rectification section. The bottom solution is recycled by pump C-1 top is partially condensed in the Ammonia condenser E-9 A/B. From here the liquid and gaseous NH3 phases are sent to the Ammonia receiver V-1. The inerts gases, saturated with ammonia, leaving the receiver, enter the Ammonia recovery tower (C-5) where additional amount of ammonia is condensed by the cold ammonia from the Urea plant battery limits. The condensed ammonia is recovered in V-1. The inert gases, containing residue ammonia, are sent to the medium pressure falling film absorber (E-11), where they meet a countercurrent water flow which absorbs gaseous ammonia. The absorption heat is removed by cooling water. From the bottom of E-11 the water ammonia solution is recycled back to the medium pressure absorber C-1 by means of pump P-7 A/B. The upper part of the medium pressure absorber consists of 3 valve trays (C- 3) where the inter gases are submitted to a final washing by means of the same absorption water. In this way the inert are collected to blow down practically free from ammonia. Low Pressure Section: Residual carbonate decomposition Carbonate recovery WWT section gas recovery The solution leaving the bottom of medium pressure decomposer is expanded at 4.5 ata pressure nad enters the low pressure decomposer E-3. This is divided into two parts: Top separator (MV-3) where the released flash gases are removed before the solution enters the tube bundle. Decomposition section where the last residual carbamate is decomposed and the required heat is supplied by means of 4.5 ata saturated steam. The gases leaving the top separator are sent to the low pressure condenser (E-8) where they are absorbed in an aqueous carbonate solution coming from the waste water treatment section. The absorption and condensation heat is removed by cooling water. From the condenser bottom, the liquid phase, with the remaining inert gases, is sent to the carbonate solution tank (V-3). From here the carbonate solution is recycled back to the medium pressure condenser E-7 by means of pump P-3 A/B.

- 18. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) The inert gases which essentially contain ammonia vapour flow directly into the low pressure falling film absorber (E-12), where ammonia is absorbed by a countercurrent water flow. The absorption heat is removed by cooling water. The inert gases, washed in the low pressure intert washing tower C-4 are collected to Blow down practically free from ammonia. Vacuum Evaporation Section Urea concentration in tow section (0.3 and 0.03 ata) Urea solution storage and recovery Urea concentration section. As it is necessary in order to prills urea, to concentrate the urea solution up to 99.7% a vacuum concentration section in two stages is provided. The solution leaving the low pressure decomposer bottom with about 71% UREA is sent to the pre concentrator this solution having urea concentration E-14 operating at a pressure of 0.3 ata. Urea concentration section. The mixed phase coming out E-14 enters the gas liquid separator MV-6 from where vapors are extracted by the first vacuum system ME-4 while the solution enters the second vacuum concentrator E-15 operating at a pressure of 0.03 ata. The two concentration are fed by saturated steam at 4.5 ata. Urea concentration section. The mixed phase coming out of E-15 enters the gas liquid separator MV-7 from where vapors are extracted by the second vacuum system ME- 5. Material of Construction. Compostion of Materials used in urea plant. Constituents 2RE 69 316L (Mod) 316 L 304 304L HVD-(duplex) Cr 25% 16-18% 16-18% 18-20% 18% 24-27% Ni 22% 10-13% 12-18% 8-11% 11% 7-9% Mo 2% 2-3% 2-3% 0.2-2% <0.4% 2-3% N2 0.2% - - C <0.08% 0.035% <0.03% <0.08% <0.03% Rector – Liner SS316 L (mod) Trays – 2 RE 69 Stripper Bimetallic tubes – Inner tube Zerconium Outer – 2 RE – 69 Dome – 2 RE – 69

- 19. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) MP Section equipment – SS – 316 L MV - 2 liner – SS 316 L, C-1-SS 316L, R -2-SS 316L LP vessel, MV – 3- liner – SS – 304L, C-2 SS 304 L Vacuum Section Equipment – SS 304 L Urea Prilling The melted urea leaving the second vacuum separator is sent to the Prilling bucket. ME – 8A/B by means of pump P-8 A/B. The urea coming out of the bucket in the form of drops along the Prilling tower ME-6 and encounters a cold air flow which causes its specification. Urea Prilling. The solid prills falling to the bottom of the Prilling towers are sent into the bely conveyor MT-1 by the rotary scrapper ME-10. From here they are sent through lumps separator ME-11 to retain lumps only and then to the product belt conveyor MT-3 which carries the product to the Urea storage section. Urea lumps by means of Urea recycle belt conveyor MT-2 are recycled back to the underground Urea lumps dissolving tank V-4 where they are dissolved. The Prills from prilling tower bottom sent to bulk flow cooler when the temp more than 65°C. In the month of May and June the BFC take in line.

- 20. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) UREA – II (P) EQUIPMENTS LIST 31 UNIT S.No. Equipment Description Tag No. 1 MPAbsorber 31-C-1 2 Distillation Tower 31-C-2 3 STRIPPER 31-E-1 4 HPAMMONIA PREHEATER 31-E-4 5 CARBAMATE CONDENSOR 31-E-5 6 MP CONDENSER 31-E-7 7 AMMONIA CONDENSER 31-E-9 A/B 8 LP CONDENSOR 31-E-8 9 MPAMMONIAABSORBER / INTERT GAS WASHING TOWER 31-E-31/C-3 10 LP AMMONIAABSORBER /INTERT GAS WASHING TOWER 31-E-12/C-4 11 I VACUUM CONCENTRATOR 31-E-14A/B 12 II VACUUM CONCENTRTOR 31-E-15 13 DISTILLATION TOWER OVERHEAD CONSENSER 31-E-17 14 DISTILLATION TOWER OVERHEAD PREHEATER 31-E-18 15 HYDROLYSER PREHEATER 31-E-19A/B 16 PURIFIED WASTEWATER COOLER 31-E-20A/B 17 STEAM CONDENSER COOLER 31-E-41 A/B 18 I INTERSTAGE COOLER (K-1) 31-E-25 19 II INTERSTAGE COOLER (K-1) 31-E-26 20 III INTERSTAGE COOLER (K-1) 31-E-27 21 FINAL STEAM CONDENSER COOLER 31-E-30A/B 22 I AND II VACUUM SYSTEM CONDENSERS 31-E-41,42 23 CARBAMATE RECYCLE EJECTOR 31-EJ-1 24 CO2 COMP 31-K-1 25 PASSIVATION AIR COMP TO K -1 31-K-2 A/B

- 21. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) 26 PASSVATION AIR COMP TO CT 08 K-2A/B 27 I AND II VACUUM SYSTEM 31-ME-4/5 28 PRILLING BUCKET 31-ME-8 29 PRILLING BUCKET SUPPORT 31-ME-9 30 ROTARY SCRAPPER 31-ME-10 31 BLOW DOWN 31-ME-14 32 FIRST VENT STACK 31-ME-15 33 DISCOIL 31-ME-20 34 II VENT STACK 31-ME-41 35 HPAMMONIA FEED PUMP MOTOR 31-MP-1 A/B 36 CARBAMATE SEPERATOR 31-MV-1 37 MP DECOMPOSER 31-ME-2, E-2, ME-2 38 LP DECOMPOSER 31-MV-3,E-3,ME-3 39 STRIPPER STEAM COND SEPERATOR 31-MV-4 40 I VACUUM SEPERATOR 31-MV-6 41 II VACUUM SEPERATOR 31-MV-7 42 CO2 COMP DELIVERY DRUM 31-MV-8 43 CO2 COMP K O DRUM 31-MV-9 44 I INTERSTAGE SEPERATOR (K-1) 31-MV-16 45 II INTERSTAGE SEPERATOR (K-1) 31-MV-17 46 III INTERSTAGE SEPERATOR (K-1) 31-MV-18 47 HPAMMONIA FEED PUMP 31-P-1A/B 48 COOLING WATER PUMPS 08-P-1-A/B 49 HP CARBAMATE SOLUTION PUMP 31-P-2 A/B 50 MP CARBAMATE SOLUTION PUMP 31-P-3 A/B 51 CW CIRCULATION PUMP FOR E-7 31-P-4 A/B 52 AMMONIA BOOSTER PUMP 31-P-5 A/B 53 MP STEAM COND FLUSING PUMP 31-P-6 A/B 54 AMMONIA SOLUTION PUMP 31-P-7 A/B 55 UREA MELT PUMP 31-P-8 A/B 56 UREA SOLUTION PUMP FOR V-5 31-P-9 A/B

- 22. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) 57 HP WASHNING PUMP 31-P-11 A/B 58 DRAIN RECOVERY PUMP FOR V-7 31-P-12 A/B 59 STEAM COND TO B.L. PUMP 31-P-13 A/B 60 HYDROLYSER FEED PUMP 31-P-14- A/B 61 DISTILLATION TOWER REFLUX FEED PUMP 31-P-15 A/B 62 C2 FEED PUMPS 31-P-16 A/B 63 STRIPPER DP CELL FLUSH PUMP 31-P-17 A/B 64 PURIFIED WASTE WATER PUMP 31-P-18 A/B 65 UREA SOLUTION RECOVERY PUMP – V-4 31-P-19 A/B/C 66 CARBAMATE SOLUTION RECOVERY PUMPS 31-P-20 A 67 BUFFER WATESWATER TANK FEED PUMPS 31-P-41 A/B 68 OILY WATER PUMPS 31-P-23 A/B 69 COND PUMP OF TK-1 31-P-27 A/B 70 EFFLUENT DISPOSAL PUMPS 31-P-33 A/B 71 UREA REACTOR 31-R-1 72 HYDROLYSER 31-R-2 73 TURBINE FOR K-1 31-TK-1 74 AMMONIA RECEIVER 31-V-1 75 STEAM CONDENSER TANK 31-V-2 76 CARBAMATE SOLUTION TANK 31-V-3 77 UREA LUMP DISSOLVING TANK 31-V-4 78 UREA SOLUTION TANK 31-V-5 79 BUFFER WASTEWATER TANK 31-V-6 80 DRAIN COLLECTING TANK 31-V-7 81 REFLIUX ACCUMULATOR 31-V-8 82 WASTEWATER TANK 31-V-9 83 SLOP OIL TANK 31-V-20 84 INSTRUMENT AIR RECIVER TANK 31-V-41 85 MAIN OIL PUMP FOR K-1 31-P-24 A/B 86 EMERGENCY OIL PUMP FOR K-1 31 – P- 25 87 CONDENSATE COOLER 31 E-13

- 23. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) UREA – II (P) EQUIPMENT LIST 41 UNIT SR.NO. EQUIPMENT DESCRIPTION TAG NO 1 MPABSORBER 41-C-1 2 STRIPPER 41-E-1 3 HP AMMONIA PREHEATER 41-E-4 4 CARBAMATE CONDENSOR 41-E-5 5 MP CONDENSOR 41-E-7 6 LP CONDENSOR 41-E-8 7 AMMONIA CONDENSOR 41-E-9A/B 8 MP AMMONIAABSORBER / INERT GAS WASHING TOWER 41-E-31 / C-3 9 LPAMMONIAABSORBER / INTERT GAS WASHING TOWER 41-E-12/C-4 10 II VACUUM CONCENTRATOR 41-E-15 11 I VACUUM COOLER (K-1) 41-E-25 12 II INTERSTAGE COOLER (K-1) 41-E-26 13 III INTERSTAGE COOLER (K-1) 41-E-27 14 I AND II VACUUM SYSTEM CONDENSERS 41-E-41,42 15 CARBAMATE RECYCLE EJECTOR 41-EJ-1 16 CO2 COMP 41-K-1 17 PASSIVATION AIR COMP TO K-1 41-K2- A/B 18 I AND II VACUUM SYSTEM 41-MP-4/5 19 HPAMMONIA FEED PUMP MOTOR 41-MP-1 A/B 20 CARBAMATE SEPARATOR 41-MV-1 21 MP DECOMPOSER 41-MV-2, E-2, ME-2 22 LP DECOMPOSER 41-MV-2, E-3, ME-2 23 STRIPPER STEAM COND SEPERATOR 41-MV-4 24 I VACUUM SEPERATOR 41-MV-6

- 24. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) 25 II VACUUM SEPERATOR 41-MV-7 26 CO2 COMP DELIVERY DRUM 41-MV-8 27 CO2 COMP K O DRUM 41-MV-9 28 I INTERSTAGE SEPERATOR (K-1) 41-MV-16 29 II INTERSTAGE SEPERATOR (K-1) 41-MV-17 30 III INTERSTAGE SEPERATOR (K-1) 41-MV-18 31 HPAMMONIA FEED PUMP 41 P-1 A/B 32 HP CARBAMATE SOLUTION PUMP 41 P-2 A/B 33 MP CIRCULATION PUMP FOR E-7 41-P-3-A/B 34 CW CIRCULATION PUMP FOR E-7 41-P-4-A/B 35 AMMONIA BOOSTER PUMP 41-P-5-A/B 36 AMMONIA SOLUTION PUMP 41-P-7 A/B 37 UREA MELT PUMP 41-P-8 A/B 38 DRAIN RECOVERY PUMPS FOR V-7 41-P-12 A/B 39 STRIPPER DP CELL FLUSH PUMP 41-P-17- A/B 40 BUF FER WASTEWATER TANK FEED PUMPS 41-P-21 A/B 41 COND PUMP OF TK-1 41-P-27-A/B 42 UREA REACTOR 41-R-1 43 TURBINE FOR K-1 41-TK-1 44 AMMONIA RECEIVER 41-V-1 45 CARBAMATE SOLUTION TANK 41-V-3 46 DRAIN COLLECTING TANK 41-V-7 47 WASTEWATER TANK 41-V-9 48 MAIN OIL PUMP FOR K -1 41 P -24 A/B 49 EMERGENCY OIL PUMP FOR K -1 41 P -25

- 25. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) UREA – 2 (PRODUCTION) EQUIPMENT LIST (after revamp) Equipment 31/41 pre-decomposer (e-53) along with booster ejector (EJ-53) and condensate separator (MV-53) 31/41 Pre-Concentrator (MV-52) along with dedicated Vacuum System and Urea pump (P-5) 31/41 New waste water tank (V-10) along with pump and motor (P-52) 31/41 replacement of carbamate ejector (EJ-1) 31/41 Replacement of carbamate ejector (Ej-1) 31/41 Heat Exchanger E-46,47 & 48 31/41 Scrubber LC 101 31/41 ejectors for pre conc system EJ-101 & EJ-102 31/41 Level Control Valve (LV 1007) 31/41 Level Control Valve (LV 1006) 31/41 Wastewater Pump P-52 A/B 31/41 Preconcentrator urea pump P-50 A/B 31/41 NG Flow control valve (FV 1007) 31/41 Ejector System for pre decomposer (EJ-63) 31/41 Condensate separator (MV-53) modified of MV-4 31/41 Pressure Control valve for ejector PV 1001 31/41 Pressure Control valve for Vaccum PV 1002

- 26. Re-Prepared by Stubborn Engineer / Rahul Jarariya Wri en by Prem Baboo (Sr.Manager (Prod), , Na onal Fer lizer Limited, Vijaypur. (2017-18) Vacuum system EJ-42B Vacuum Ejector Ej-2B and Ej-3B Ammonia Scrubber C-102 Steam Condensate separator V-29 Bulk Flow Cooler LIC 502 Control Valve for DM water tank P-60 A/B Water Circulation Pump Plate type Heat Exchanger ET -21 B Product dich Belt High Rise Belt ET-21A Two Number AC System TIC 503 Temp Control Valve FD Blower Stem Coil Air Heater Inst Air Vibrator TIC 501 Temp Control Valve PRV 501 Pressure Control Valve